In this fast-paced world, preserving the freshness of food is essential to minimize waste and save money. Possibly, the use of nitrogen generators supported by modern technologies has brought a new opportunity that anyone could, at least to a certain degree extends the lifetime of the food. In this blog, we will be looking at several strategies on how food prolonged function and how to maintain its freshness. It involves using the process of limiting the oxygen supply to the packaged food items, which is usually a small 1-5% concentration of oxygen. The action of MAP phase is about oxygen bubble being replaced with PSA Nitrogen Generator Gas which is used with all kinds of food packaging (meat, chips, namkeens, fish, etc.)

Table of Contents

What do we mean by Modified Atmosphere Packaging?

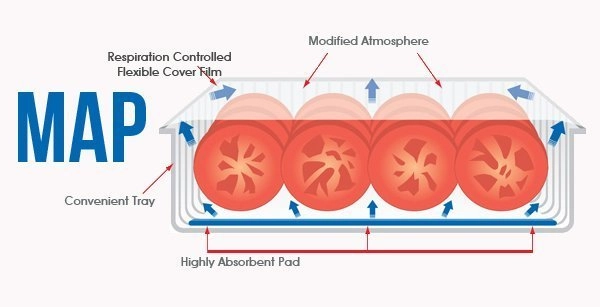

MAP is a process of assembling the packages in an oxygen-deprived atmosphere, the oxygen concentration usually being in the range between 1-5%. In MAP, Oxygen is systematically replaced with another gas, in this case, nitrogen, and this is a common O2 replacement method.

How Does Nitrogen Preserve Food?

Nitrogen, being an inactive gas, doesn’t allow air respiration to take place and prevents the contortion of product shape. The gas flushing system replaces oxygen with nitrogen that is pumped into canned products, packaged chips, namkeens, etc. and secures them at the same time. This process protects these products from any form of spoilage. Nitrogen generators offer a cost-effective and convenient solution, ensuring on-demand nitrogen supply without reliance on third-party vendors.

Benefits of Nitrogen Preservation:

Prevents discoloration and enzymatic browning

Reduces spoilage and nutrient loss

Preserves texture and flavour

Increases shelf life and prevents microbiological growth

Food freshness is kept intact with nitrogen generators, which provide oxygen less atmosphere. The oxygen is one of the major factors that cause food deterioration, because it lets bacteria and Mold grow. As nitrogen is employed instead of air in the packaging, it reduces the growth of microorganisms that can spoil the food, and oxidation process that tends to lower the food quality. This helps them remain fresh and tasty for a longer period of time.

Preservation Methods:

Not only does nitrogen packing have a variety of preservation methods but also, they can be used to elongate your food products shelf life. Canning, freezing, vacuum packaging, and dehydrating are efficient methods that apply in the case with fruit, vegetable, meat preservation, and many more kinds of fresh items.

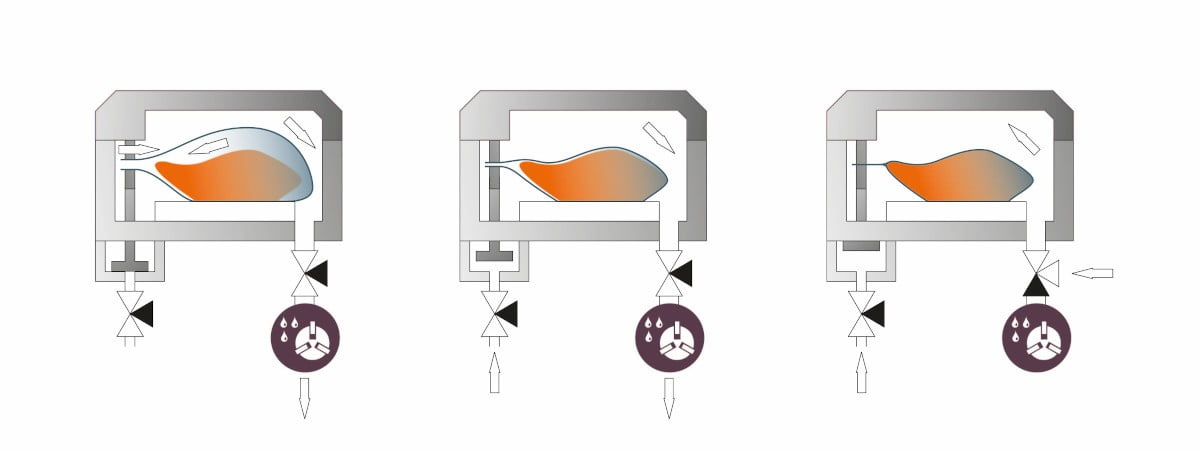

Vacuum Packaging Method:

Vacuum packaging with nitrogen involves removing air from a package to create a vacuum and then replacing it with Nitrogen generator gas. This process helps to preserve food by reducing oxygen levels, slowing down oxidation, and inhibiting the growth of aerobic bacteria. The nitrogen acts as a protective atmosphere, extending the shelf life of the packaged food and maintaining its quality and freshness.

Rely on Absstem for your Nitrogen Solutions

Absstem is India’s leading nitrogen generators manufacturing firms. We can boast an equitable and diverse scope that incorporates standard and custom nitrogen generators for the food processing and packaging industries. Trust us to deliver reliable and efficient solutions that meet your unique requirements and elevate your operations.

Conclusion

Carrying out easy tactics such as proper storage, vacuum with nitrogen generator and preservation can significantly reduce food waste and increase food shelf-life. Using nitrogen generators in the airtight packing is a really smart decision for enterprises as it’s cheapest and most effective solution of supplying food with guaranteed freshness.

| Also Read: – Nitrogen Generator: A Game-Changer in Food Packaging |

References:

Freshness and Shelf Life of Foods

Global Food and Beverage Nitrogen Generators Industry Research Report