Nitrogen Generators for the Food Industry: Preserving Freshness and Quality

All New nGENX

Industrial Nitrogen Generators (nGENX)

nGENX is the next generation and advanced Nitrogen Generator for food packaging being developed to ensure that the food packaging process has a constant source of Nitrogen. Due to the application of latest PSA (Pressure Swing Adsorption) technology, nGENX provides purity nitrogen for food application. It assists in retention of freshness, increase shelf life as well as ensuring high quality of your products. nGENX offers food packaging a competitively priced and scalable solution that delivers the necessary performance standards required by this market segment while increasing factory uptime and reliability.

Features

EIGA E-941 Compliant Nitrogen

Compact and Ergonomically Designed

Plug n Play

60-minute Plant Commissioning

Lowest Power Consumption

IoT-Ready

Remote Monitoring Enabled

Designed for 24x7 Operation

Hydrocarbon Free Nitrogen

10 years Warranty

EIGA E-941 Compliant Nitrogen

Compact and Ergonomically Designed

Plug n Play

60-minute Plant Commissioning

Lowest Power Consumption

IoT-Ready

Remote Monitoring Enabled

Designed for 24x7 Operation

Hydrocarbon Free Nitrogen

10 years Warranty

Benefits

No Delivery Bottlenecks

Constant Supply

Safety

Consistent Purity

Constant Supply

Safety

- Temperature

- Pressure

- Pressure dewpoint

- Automatic feed air blow-off in case of contamination

- Very High Density due to packed-bed Technology

- Protected by the dedicated pressure sensor

- 10-year warranty on CMS*

- Filters remove oil and dust particles

- Additional filters drain moisture using an ADV (Automatic Drain Valve)

- Eliminates the risk of overflow and CMS damage

- Lowest Air factor (Air-to-Nitrogen ratio) from 1.8 (95% N2) in the industry

- Self-regulation and stable purity

- Stand-by mode in case no Nitrogen is consumed

- Automatically regulates the requested nitrogen pressure and purity

Working Gas Separation

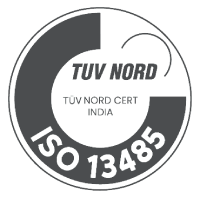

The industrial nitrogen generator consists of two adsorbers filled with carbon molecular sieves (CMS). Pressurized air is passed through one of these adsorbers with Carbon, having a structure to attract oxygen, adsorbs oxygen from the air and nitrogen is allowed to pass through to the storage tank and is produced as the final product. As the adsorber approaches saturation, the air is allowed to pass through the other adsorber while this adsorber is being regenerated to ensure a continuous supply of industrial nitrogen.

This changeover takes place through a specially designed micro controller to ensure a hassle-free operation. The quality of nitrogen produced is continuously monitored by a nitrogen analyzer.

Engineering

The integral components of nGENX include: –

Alarm management system

Process data display

Service planning element

Display of consumable’s running hours

Data logging via USB drive

Graphical representation

Additional Upgrades

Digital flow meter with totaliser

High pressure nitrogen tank

Cylinder manifold and alarm management system

Remote monitoring

STATS Technical Data

Lowest specific power in the industry

Inlet air as per ISO 8573.1:2010 – Class 1.4.1

Pressure up to 350kg/cm²g is available on demand through N2 compressors

Maximum relative humidity is 95%

Purity testing is done by NABL APPROVED lab

Sound level of 65 dB from a distance of 1 meter

Working temperature is -5° C to 50° C

Nitrogen Flow up to 3000 Nm³/hr

Purity up to 99.999%

USB Storage to store parameters values

CE-certified electronics with 24 VDC Operating Voltage

All tanks are fabricated per ASME standards

All tanks have a corrosion-resistant internal environment

ISO 9001:2015: Manufacturing is in accordance with certified QMS (Quality Management System)

Systems Packaged Solutions

PSA Nitrogen Generator

This is a plug and play system

Requires dry compressed air and one storage tank only

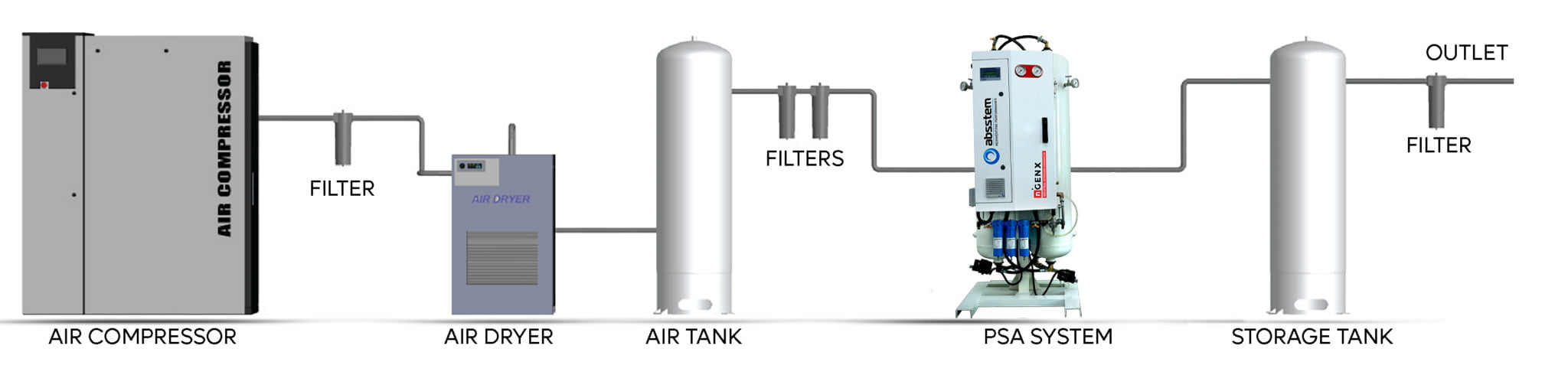

Skid Package System

This system comes with air compressor, multistage filtration system, nGENX and nitrogen compatible storage vessel.

This is a complete package with all instruments

Compressor Auxiliary Equipment

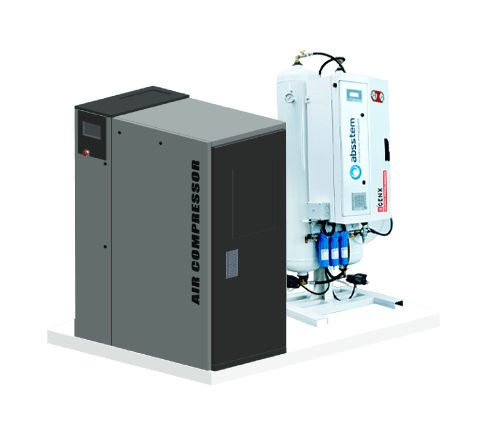

High-Pressure Nitrogen Cylinder filling System

PSA Nitrogen generator with Nitrogen booster compressor for filling of cylinders

Cylinders filled up to 350 Barg pressure

Cylinders filling range/day is 8 to 1000 Nos.

High-Pressure Nitrogen up to 70 Barg

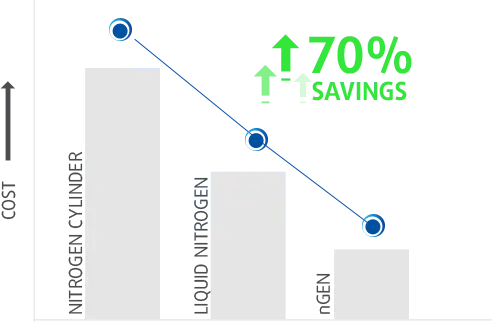

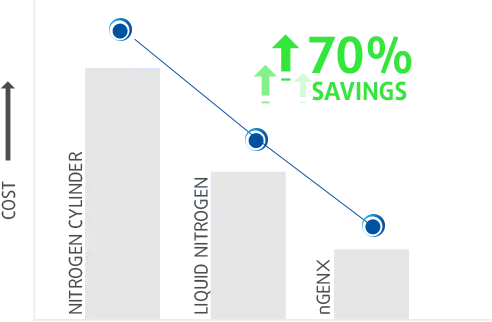

ROI Return on Investment

With great emphasis on cost-effective, low-impact business practices, most businesses opt for bulk delivery to meet all their industrial gas requirements. But given the fluctuation in market prices of gases like oxygen and nitrogen, this is no more a viable option. A large number of industries are using onsite gas generation plants for reliability and improved ROI.

ROI Return on Investment

With great emphasis on cost-effective, low-impact business practices, most businesses opt for bulk delivery to meet all their industrial gas requirements. But given the fluctuation in market prices of gases like oxygen and nitrogen, this is no more a viable option. A large number of industries are using onsite gas generation plants for reliability and improved ROI.

Utilities Applications

Food Packaging

Brochure Download

FAQs Frequently Asked Questions

Depends on the purity requirement (95-99.9995%) and LPM consumption. Please contact us for an estimated cost.

Primarily, you need to understand the purity required for your specific application along with the volume required.

Very Reliable. These machines are built to last. Our generators have the lowest Production Downtimes the industry has to offer.

PSA stands for Pressure Swing Adsorption, and it is a technology used to separate gases based on the differences in their adsorption rates onto a solid material. Membrane nitrogen generators, on the other hand, use a semipermeable membrane to separate nitrogen from other gases. Both PSA and membrane nitrogen generators are used to produce high-purity nitrogen gas from air, but they use different principles and technologies to do so.

PSA nitrogen generators work by passing air through a vessel filled with an adsorbent material, such as carbon. The nitrogen in the air is preferentially adsorbed onto the adsorbent material, while the other gases pass through. By cycling the pressure in the vessel and switching between two or more adsorbent beds, the PSA system is able to continuously produce high-purity nitrogen gas.

Membrane nitrogen generators, on the other hand, use a membrane to selectively allow nitrogen molecules to pass through while rejecting other gases. The air is passed through the membrane under pressure, and the nitrogen is separated out as it diffuses through the membrane. Membrane nitrogen generators can also produce high-purity nitrogen, but they tend to have lower capacity and require a higher pressure drop across the membrane compared to PSA systems.

One advantage of PSA nitrogen generators is that they tend to have higher capacity and can produce nitrogen with higher purity compared to membrane systems. They also tend to be more reliable and require less maintenance. Membrane nitrogen generators tend to be smaller and more compact, making them suitable for applications where space is limited. However, they have lower capacity and may not be able to produce nitrogen with as high of a purity as PSA systems. They also have a limited lifespan and may require more frequent maintenance.

In general, PSA nitrogen generators are a good choice for applications that require high-purity nitrogen at a large scale, while membrane nitrogen generators may be more suitable for smaller, more specialized applications. Ultimately, the decision between PSA and membrane nitrogen generators should be based on a careful evaluation of the specific requirements of the application and a cost-benefit analysis.

With proper and consistent maintenance these machines can run for over 10 years.