Complete On-Site Oxygen and Nitrogen PSA Plants for Healthcare and Industries in India

Designed, Manufactured, Installed & Commissioned by Absstem

Absstem delivers complete on-site oxygen and nitrogen generation plants using advanced PSA (Pressure Swing Adsorption) technology. Turnkey delivery from design and manufacturing to installation, commissioning and long-term support.

Efficient. Automated. Self-Reliant. Built for 24/7 Operations.

Why Choose Absstem?

Complete On-Site PSA Plant

Absstem delivers end-to-end execution of your gas generation system, covering application study, plant design, in-house manufacturing, on-site installation and commissioning, operator training, and long-term service, ensuring a fully commissioned, ready-to-use PSA plant, not just equipment.

Adsorption & PSA Technology Specialists

As adsorption technology specialists, we continuously optimise PSA cycles and molecular sieve performance to deliver stable purity, energy efficiency, and long service life across medical and industrial gas applications.

Pioneer of PSA Systems in India

Proudly Made in India, Absstem manufactures a complete range of PSA-based oxygen and nitrogen plants with end-to-end capabilities in engineering, assembly, testing, customisation, and long-term servicing.

Reliable On-Site Gas Supply

Our PSA plants generate oxygen and nitrogen directly from atmospheric air, delivering dependable on-site gas supply with zero cylinder dependency, consistent purity and pressure, and uninterrupted 24/7 operation.

250+ Installations Across India

With over 250 installations across 25+ States and multiple Union Territories, Absstem supports leading hospitals and industries nationwide with proven, reliable on-site PSA gas generation systems.

Certified, Compliant & Award-Winning

As one of India’s only ISO 13485-certified medical oxygen plant manufacturers (TÜV Nord) and a recipient of the Aegis Graham Bell Award for Innovative Medical Equipment, Absstem designs and delivers PSA-based systems that meet the highest Indian and global quality, safety, and compliance standards.

R&D-Driven Innovation

At Absstem, we are committed to the continuous advancement of adsorption technology, focusing on refined operational cycles and next-generation adsorbents for cleaner, more cost-effective gas production.

Industries We Serve

Absstem installs on-site PSA plants tailored to purity, pressure, and flow requirements.

Healthcare

Metal Processing & Metallurgy

Oil and Gas

Chemical Industry

Food & Beverage

Electronics Manufacturing

Laser Cuttig

Pharmaceuticals

Tyre Manufacturing

Steel & Metal Industry

Ozone Generation

Wastewater Treatment

Pulp & Paper

Aquaculture

3D Printing

Power Plant

How On-Site PSA Gas Generation Works

Air Intake

Filtered and compressed atmospheric air enters the PSA system.

PSA Separation

Advanced molecular sieves selectively separate oxygen or nitrogen using pressure swing adsorption.

On-Demand Gas Delivery

High-purity gas is delivered directly to pipelines or equipment continuously, safely, and automatically.

Typical On-Site Plant Performance

- Oxygen purity: 93–96%

- Energy-efficient operating cycles

- Energy-efficient operating cycles

- IIoT-enabled remote monitoring

Trusted by Leading Hospitals & Industries

About Absstem

Founded in 2017, Absstem is one of India’s pioneering manufacturers of PSA-based on-site oxygen and nitrogen generation plants. Recognised by the Government of India, DIPP, and Startup India, we deliver complete responsibility, from design and manufacturing to installation and long-term servicing.

Our expertise includes:

- Medical oxygen PSA plants for hospitals

- Industrial oxygen and nitrogen PSA plants

- CMC and AMC for existing PSA oxygen and nitrogen plants

- Custom-engineered PSA solutions

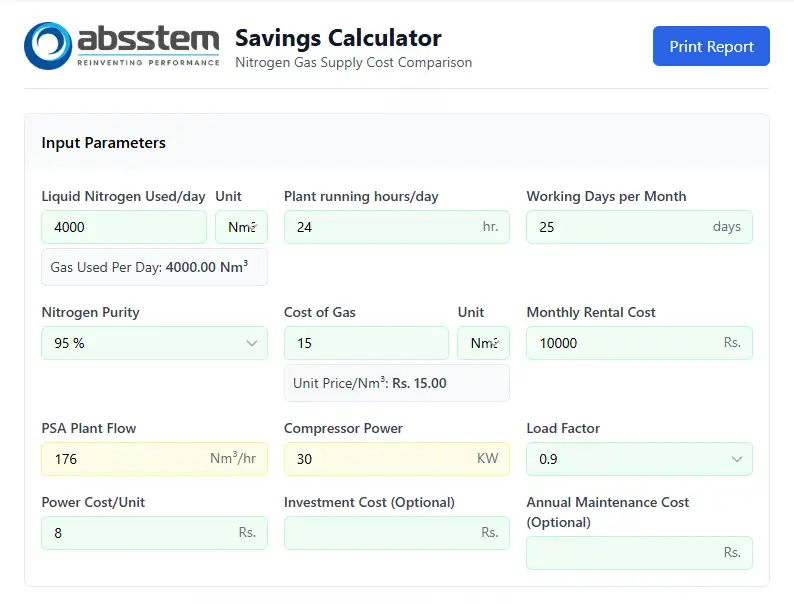

Achieve Significant Cost Savings

- Save up to 80% compared to cylinders or liquid oxygen / nitrogen

- Zero transportation and rental charges

- Reduced operational and safety risks

- Typical payback within 12–18 months

Pan-India Service & Support

- Nationwide service coverage

- Trained PSA engineers

- IIoT-based remote diagnostics

- Predictive maintenance

- Rapid spare parts availability

You operate 24/7, and so do we.

Start Your Transition to On-Site Gas Generation

Tell us your requirements and our experts will respond within 24 hours.

-

Ladakh

-

Jammu & Kashmir

-

Himachal Pradesh

-

Punjab

-

Uttarakhand

-

Delhi

-

Haryana

-

Rajasthan

-

Uttar Pradesh

-

Bihar

-

Jharkhand

-

West Bangal

-

Madhya Pradesh

-

Gujarat

-

Maharashtra

-

Chhattisgarh

-

Odisha

-

Telangana

-

Karnataka

-

Andhra Pradesh

-

Tamil Nadu

-

Lakshadweep

-

Assam

-

Arunchal Pradesh

-

Manipur

-

Mizoram

-

Nagaland