In the rapidly evolving world of additive manufacturing, particularly 3D metal printing, the choice of gases used during the process can significantly impact the quality and efficiency of printed products. Among these gases, nitrogen plays a crucial role. This blog explores the benefits of using nitrogen generators in 3D metal printing, highlighting how they enhance the printing process and improve the final product quality.

Table of Contents

Understanding 3D Metal Printing

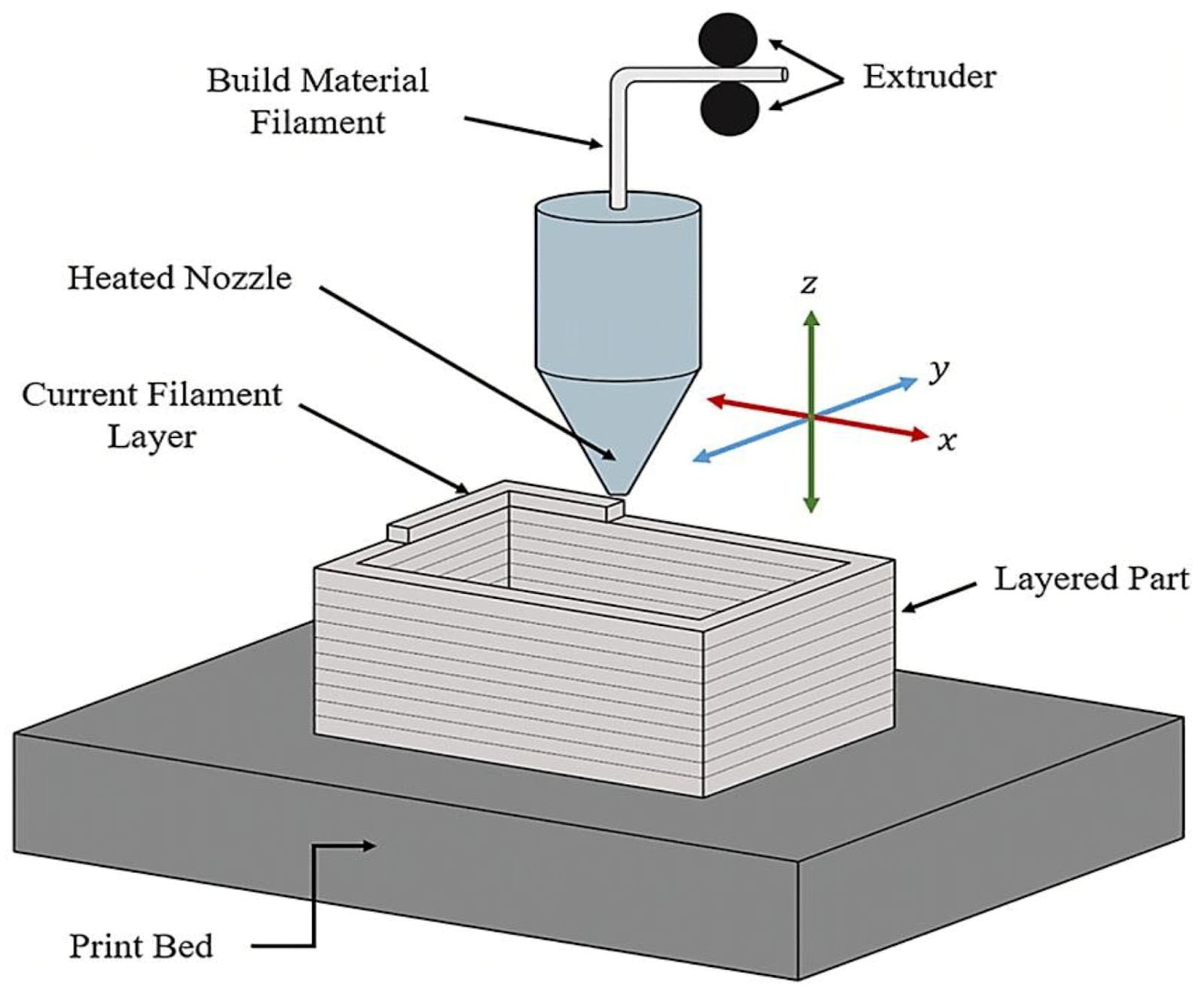

3D metal printing, also referred to as metal AM or direct metal laser sintering, is the process of creating metal parts using a digital 3D model where the metal components are printed in a layer-by-layer format. This method is especially popular in aerospace, automotive, and healthcare industries because it can create intricate shapes that are otherwise difficult to manufacture using conventional processes. Central to the process are the shielding gases that maintain the atmosphere free from oxygen, which would otherwise compromise the quality of the metal used in the process.

The Importance of Nitrogen in 3D Metal Printing

Nitrogen, an inert gas, is commonly used in 3D metal printing for several reasons:

Oxidation Prevention: When it comes to printing, they use metal powder or filament that undergoes high temperatures. Nitrogen has the property of rendering an atmosphere non-reactive and thereby shields the metal from oxygen. This is important for supporting the microarchitectural structure and quality of the printed part.

Cost-Effectiveness: The cost of nitrogen, compared with other inert gases such as argon, is relatively cheaper. This makes it a popular option, especially if large amounts of gas are needed, as might be the case with industrial applications.

Availability: Nitrogen is relatively cheap, easily availed since it is found in large quantities in the air and the use of nitrogen generators makes its production easier.

Benefits of Using Nitrogen Generator in 3D Printing

Nitrogen generators offer several advantages for 3D metal printing operations:

Continuous Supply: Nitrogen generators ensure a continuous and reliable supply of nitrogen. This is crucial for uninterrupted printing operations, especially for large-scale industrial applications.

Cost Savings: By generating nitrogen on-site, companies can reduce the costs associated with purchasing and transporting gas cylinders. This also eliminates rental fees for gas storage tanks.

Purity Control: On-site nitrogen generators allow for control over the purity levels of the gas. This is essential in 3D printing, where even slight impurities can affect the quality of the final product.

Environmental Benefits: Generating nitrogen on-site reduces the carbon footprint associated with the transportation and handling of gas cylinders. It also minimizes the waste associated with empty gas cylinders.

Safety and Convenience: On-site generation reduces the risks associated with storing and handling high-pressure gas cylinders. It also simplifies logistics, as there’s no need to manage deliveries and storage of large gas quantities.

How Nitrogen Generators Work

Nitrogen generators typically use one of two technologies: Pressure Swing Adsorption (PSA) or Membrane Separation.

PSA Technology: This method involves passing compressed air through a vessel containing a carbon molecular sieve. The sieve adsorbs oxygen, allowing nitrogen to pass through. The result is high-purity nitrogen suitable for 3D printing applications.

Membrane Separation: In this method, compressed air is passed through a membrane that selectively permeates oxygen, leaving behind nitrogen. This method is simpler and often used for applications requiring lower nitrogen purity.

Get in touch with Absstem!

Get in touch with Absstem today for reliable and cost-effective nitrogen generators, ensuring a continuous supply of high-purity nitrogen for your 3D printing needs. Contact us now!

Drop a line to get a quote or talk to an expert to get started with your on-demand, onsite installation of PSA Nitrogen generators. To find out more about our Nitrogen Gas System Contact Us.

Conclusion

It is thus paramount to understand how to use nitrogen in 3D metal printing to come up with parts made of metal with precision. Printing requires an inert environment; the nitrogen generators provide this efficiently and economically without any side effect to the environment. By using nitrogen production in-house, 3D printing organizations can remove worries regarding the availability of supplies and ways, decrease total costs, and enhance the results of using 3D printing techniques. Therefore, nitrogen generators’ application in supporting such cutting-edge technology as additive manufacturing will continue to rise in the future due to increased use of the technology.

| Also Read: – Why Choose a PSA N2 Generator for Laser Cutting? |

References

https://www.mdpi.com/2073-4360/14/19/3971

Related posts:

- A Comprehensive Guide to PSA Nitrogen in the Metal Processing Industry

- Torch Metal Cutting Oxygen Purity 94%: The Ultimate Guide to Achieving Precision Cuts

- The Importance of PSA Oxygen Generation in Metal Fabrication

- The Role of Onsite Oxygen Generators in Brazing

- How do onsite nitrogen generators work?