Nitrogen, an essential element for various industrial processes, is often required at high purity levels. Two popular methods for nitrogen generation are Pressure Swing Adsorption (PSA) Nitrogen Generator and Membrane Nitrogen Systems.

In this comprehensive comparison, we’ll delve into the workings, advantages, and limitations of both systems to help you make an informed decision for your specific application.

Table of Contents

Pressure Swing Adsorption (PSA) Nitrogen Generators:

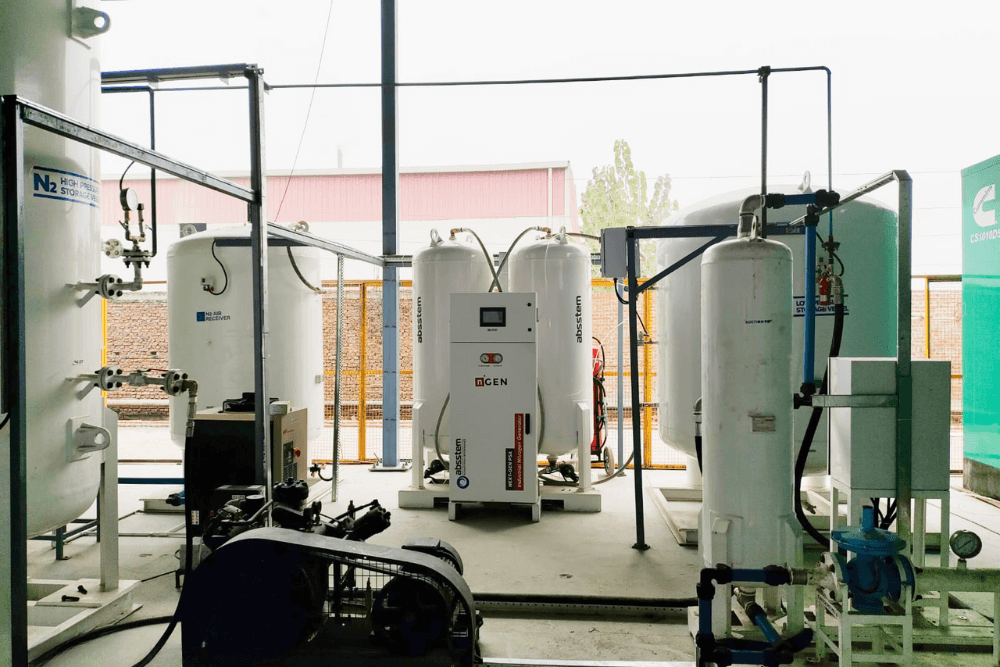

Using selective adsorption, they extract high-purity nitrogen from compressed air with a distinctive “pressure swing” mechanism. Versatile, compact, and energy-efficient, these generators find applications in electronics, food packaging, and metal fabrication. With purity levels up to 99.9995%, the PSA Nitrogen Generator offers a cost-effective and sustainable alternative, providing businesses with a customized and dependable nitrogen supply.

Principle of Operation:

PSA nitrogen generators operate on the principle of selective adsorption. They use adsorbent materials, typically carbon molecular sieves, to separate nitrogen from other gases in the air. Under pressure, oxygen and other impurities are adsorbed by the material, allowing nitrogen to pass through.

Purity Levels:

PSA systems can achieve high purity levels, often up to 99.9995%. The adjustable purity levels make them suitable for a wide range of applications, including electronics manufacturing and food packaging.

Energy Consumption:

While PSA systems are energy-efficient compared to traditional nitrogen delivery methods like cylinders, they do require a constant energy supply to operate. The energy consumption is typically lower than cryogenic methods.

Space and Mobility:

PSA systems are compact and can be easily installed on-site, offering a space-efficient solution. They are also mobile and can be moved as per the user’s requirements.

Here’s a 5 -minute read on Nitrogen Purging Techniques and PSA Nitrogen Generators

Membrane Nitrogen Systems

Principle of Operation:

Membrane nitrogen generators use semi-permeable membranes to separate nitrogen from other gases based on their molecular size. Nitrogen molecules, being smaller, permeate through the membrane, leaving oxygen and other impurities behind.

Purity Levels:

Membrane systems generally produce nitrogen with lower purity levels compared to PSA systems, typically ranging from 95% to 99.5%. This makes them suitable for applications where slightly lower purity is acceptable.

Energy Consumption:

Membrane systems are known for their low energy consumption, making them a cost-effective solution compared to cryogenic separation. They don’t require electricity during the separation process, relying on the pressure difference across the membrane.

Space and Mobility:

Membrane systems are compact and may require less space compared to PSA systems. They are relatively easy to install and can be moved if needed.

Comparative Analysis

Purity Requirements:

Choose between PSA and membrane systems based on the specific purity requirements of your application. If high purity is critical, a PSA nitrogen generator might be more suitable.

Energy Efficiency:

Consider the energy efficiency of each system in relation to your operational needs. PSA systems are often favored for their lower energy consumption.

Space and Mobility:

Assess the available space and mobility requirements at your facility. Both systems offer compact solutions, but the ease of installation and mobility may differ.

Initial Investment and Operating Costs:

Evaluate the initial investment and operating costs associated with each system. While membrane systems might have a lower initial cost, PSA systems may offer better long-term efficiency.

Conclusion:

In conclusion, the choice between PSA Nitrogen Generator and Membrane Nitrogen Systems depends on your specific application requirements. Consider factors such as purity levels, energy efficiency, space constraints, and mobility needs to make an informed decision that aligns with the goals of your industrial processes.