1: PSA Generators Only Produce Low-Purity Nitrogen.

Myth.

Explanation: PSA technology can successfully achieve purities up to 99.9995%. The system allows dynamic purity adjustment based on application requirements, optimizing operational costs. Purity levels can be precisely controlled to match specific industrial needs.

To understand more about the different purities of nitrogen via PSA nitrogen generators, please read this blog (1).

2: Liquid Nitrogen is Most Economical source of Nitrogen.

Myth.

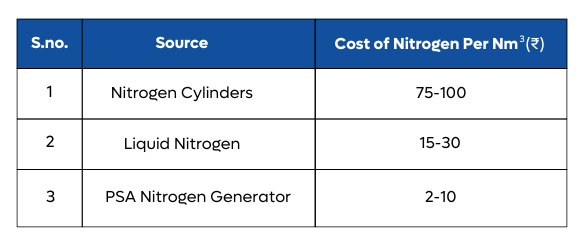

Explanation: PSA generation systems offer superior cost-effectiveness. Nitrogen production cost via a PSA system is almost 1/3rd of liquid nitrogen and 1/15th in case of nitrogen cylinders. To give a basic idea of nitrogen cost (not including the transportation cost), take a look at the table below:

The capital investment of the PSA nitrogen plant can be recovered within 12 – 24 months depending on the nitrogen requirement of the industry. The maintenance cost of PSA nitrogen plants is also fixed via a Maintenance Contract covering every consumable, damaged parts and service technician visits. We’ve spoken in depth about the cost of various sources of Nitrogen in our blog titled How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders (2) where factors like capital investment, maintenance cost etc. have been considered to calculate the ROI.

3: PSA Systems Require Dedicated Operators.

Myth.

Explanation: Modern PSA systems are fully automated with:

- Automatic start/stop functionality

- 24/7 operational capability

- Zero operator intervention needed

- Electricity as the only input requirement

4: Continuous Maintenance is required for the PSA nitrogen plant.

Reality.

Explanation: Like every machine in the industry, PSA nitrogen plants also require timely preventive maintenance including regular replacement of consumables and damaged parts (if any), and calibration of the measuring instruments. These maintenance activities are usually done by the PSA nitrogen plant supplier as a part of a comprehensive maintenance contract which covers everything from consumables to breakdown to regular technician visits thereby assuring complete peace of mind to the customer.

5: Annual Carbon Molecular Sieve Replacement is Mandatory.

Myth.

Explanation: Across the industry, an existing common myth is that some quantity of molecular sieves need to be repeatedly filled/topped up in the PSA bed as sieves get powdered over the course of time. However this happens only when the PSA bed has not been properly packed and/or the PSA plant has not been properly designed. If the PSA (molecular sieve) bed is properly packed and the PSA plant has been designed to keep the velocity of gas under limits, carbon molecular sieves will not get powdered thus eliminating the need for topping up/refilling of the sieves. Therefore, buying the PSA Nitrogen plant from a reputed OEM provides monumental life cycle cost savings if you buy a PSA, as molecular sieves are the most expensive part of any PSA plant. Absstem offers a unique 10-year warranty on molecular sieves. Please refer to our blog on molecular sieves here (3)

6: PSA nitrogen plants consume a lot of electricity.

Myth.

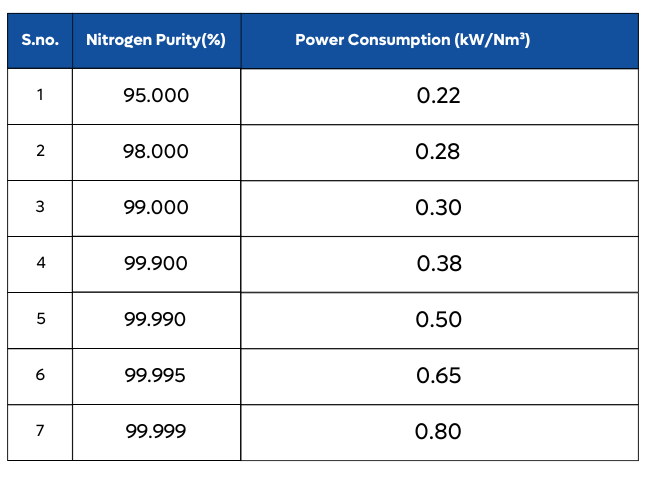

Explanation: Power consumption in a PSA nitrogen plant varies in accordance with the required nitrogen purity required from 0.22-1.2KW per Nm3 of nitrogen produced that means if the electricity cost is around ₹8/-, then the cost of 1 NM3 of nitrogen will be ₹1.76-9.6/-. PSA nitrogen plants are highly power efficient if properly designed and purchased from a reliable manufacturer. Below are the power consumption data for different purities:

7: PSA Nitrogen plants run continuously if the nitrogen requirement is less than the plant capacity.

Myth.

Explanation: Modern PSA systems feature:

- Automatic IDLE mode during low-demand

- Dynamic power consumption adjustment

- Efficient energy management

- Demand-based operation

You can read more about Economy and Idle Modes in our blog here (4)

8: PSA Nitrogen Plants have Long Startup Times (1-3 Hours) to attain purity.

Myth.

Explanation: The startup time of a typical PSA nitrogen plant varies between 2-5 minutes. PSA nitrogen plants take time at the initial commissioning or during the first startup as the nitrogen storage tank contains air (20.95% oxygen) which is replaced by high-purity nitrogen from the PSA. This time can be around 3 to 6 hours depending on the size of the storage tank after which it takes only 5 minutes to start for continuous operations.

9: High Purity Nitrogen is required for all applications of Nitrogen.

Myth.

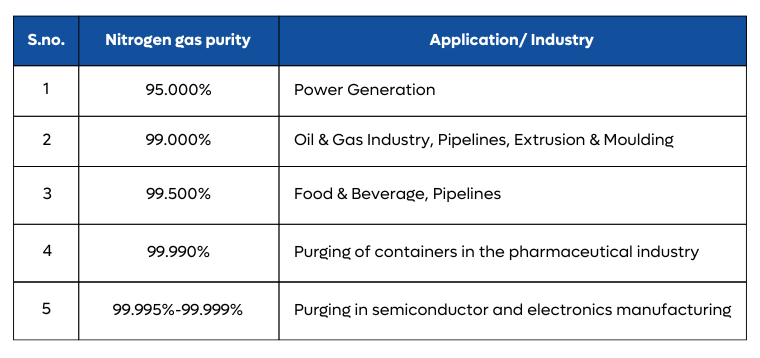

Explanation: The required purity of Nitrogen is application-specific and must not be generalised. Using high-purity nitrogen where lower purities can work leads to higher cost of generation and energy wastage. Below is the list of different applications with their nitrogen purity requirement:

Conclusion

The technical overview demonstrates that many common perceptions about PSA nitrogen generation are outdated. Modern systems offer efficient, automated, and economical nitrogen production when properly engineered and maintained.

Contact Us

For tailored solutions and expert advice on Nitrogen Generation, contact us:

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: absstem.com

References

- Absstem Technologies. (2024).Understanding Nitrogen Purity in PSA Nitrogen Generators.

- Absstem Technologies. (2024).How to Calculate the ROI (Return on Investment) of PSA Nitrogen Generator Compared to Liquid Nitrogen or Nitrogen Cylinders .

- Absstem Technologies. (2024).Understanding Molecular Sieves or Adsorbents: CMS & ZMS.

- Absstem Technologies. (2024).Understanding ECONOMY or IDLE Mode in PSA Oxygen or Nitrogen Generators.