The PSA (Pressure Swing Adsorption) Nitrogen Generators have become essential in several industries because of the performance of the Nitrogen Generators in generating high purity Nitrogen. These generators are designed to be run under varying conditions and the application of these conditions means that they are well suited to a range of environments. In this blog, topics discussed will include how PSA nitrogen generator use various working parameters and the advantages that come with the system.

Understanding PSA Nitrogen Generators

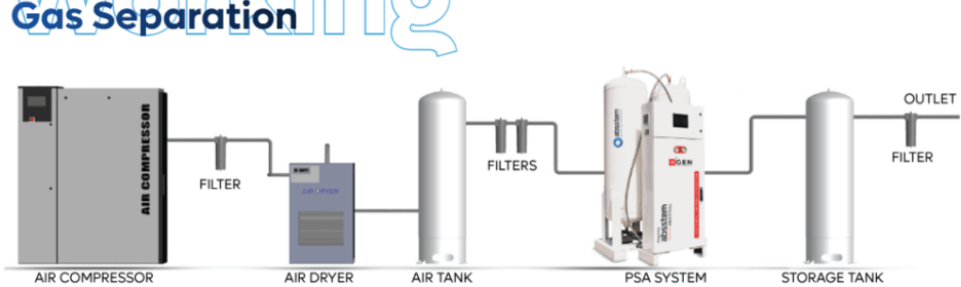

PSA nitrogen generator utilizes a technology called Pressure Swing Adsorption to effectively separate Nitrogen from other gasses in the air. This process involves two main components: carbon molecular sieves and pressure swing as well as vacuum pressure. Selective adsorption is used to trap oxygen and other unwanted gasses while nitrogen is allowed to pass through and is collected.

Key Features Enabling Adaptation

Advanced Control Systems

The PSA nitrogen generators installed in modern plants are provided with elaborate control systems that are capable of monitoring and controlling the running parameters of the process. These systems allow the equipment to operate at peak efficiency, as it is capable of adjusting to fluctuations in the temperature, pressure, and flow rates. This reduces variability in the nitrogen purity and the efficiency of the process, which is important for the process.

Robust Design

PSA nitrogen generators are designed with heavy-duty parts that can endure extreme climates. In general, it does not matter if the generator is placed in cold or hot conditions, high or low humidity areas, or even in areas with dust, its design provides it with the ability to work effectively. High-grade materials, along with rust-proof coatings add to the life expectancy of the product.

Scalability and Flexibility

One of the significant advantages of PSA nitrogen generators is their scalability. They can be customized to meet specific requirements, whether it’s for a small laboratory or a large industrial facility. This flexibility allows them to adapt to varying production demands and operating conditions seamlessly.

Energy Efficiency

PSA nitrogen generators are designed to be energy efficient. They control their operation according to the demand for nitrogen and at the time when there is little demand, they will cut down their energy consumption. This versatility is not only effective in reducing the business’s operating expenses but also in reducing the negative effects on the environment.

Remote Monitoring and Diagnostics

Most PSA nitrogen generators that are available in the market today can be monitored remotely and diagnosed. This feature enables the operators to check on the performance of the generator in real-time, and even carry out some maintenance without having to be physically present at the location of the generator. It allows for immediate adjustment to any changes in operating conditions, thereby minimizing the time taken before it is up and running again, providing a continuous supply of nitrogen.

Adsorption in PSA Nitrogen Generators

Adsorption is a critical process in PSA nitrogen generators. It involves the following steps:

Pressurization: Air is supplied to the generator and is passed through a bed of carbon molecular sieves to enhance its compressibility. The CMS filters oxygen and other unwanted gases, letting nitrogen pass through.

Depressurization: The pressure within the CMS bed is lowered, releasing the adsorbed gases and removing them out of the system.

Regeneration: After the last cycle, the CMS bed is evacuated and a small amount of nitrogen is used to flush out any impurities to prepare the CMS bed for the next cycle.

This cycle of pressurization, depressurization, and regeneration enables continuous production of high-purity nitrogen.

Advantages of PSA Nitrogen Plant

PSA nitrogen generators offer several advantages, including:

High Purity Levels: It is important to note that PSA technology can achieve nitrogen purity of up to 99%. 999%.

Cost-Effective: These generators also do away with the need to buy and transport nitrogen cylinders, factors that contribute to operational expenses.

On-Demand Production: PSA systems continuously deliver nitrogen, and this is done based on the needs of the application being served.

Environmentally Friendly: PSA generators also have the advantage of locally generating nitrogen which leads to the reduction of carbon emission from the transportation and storage of nitrogen cylinders.

Adapting to Varied Operating Conditions

PSA Nitrogen Plant are designed to adapt to a wide range of operating conditions, ensuring consistent performance in different environments. Here’s how they achieve this:

Temperature Variations: PSA nitrogen generators have sophisticated control circuits that make it possible to change the cycle times depending on temperature. This helps in achieving efficient adsorption and desorption in a short time and keeps the system pure even when exposed to high temperatures.

Pressure Fluctuations: It is important to note that the input air pressure varies and that the system must be able to adapt to it. PSA nitrogen generators utilize pressure sensors and control valves to enable steady pressure in the adsorbent beds for smooth operation.

Moisture and Contaminants: These are factors that influence the performance of the CMS and they include high moisture levels and contaminants in the input air. PSA systems generally incorporate pre-filters and dryers to help remove moisture and other contaminants before the air enters the adsorbent beds. This safeguards the CMS and also maintains high efficiency of nitrogen production.

Flow Rate Adjustments: Nitrogen flow rate depends on the given application since it may vary depending on the use. PSA nitrogen generators can be controlled to deliver the right flow rate without straining the purity aspect. This is done using variable speed compressors and flow control mechanisms in the case of multi-compressor units.

Applications Across Varied Industries

Food and Beverage Industry

PSA nitrogen generator are widely used in industries such as food and beverage packaging, preservation, and inerting. The specification to hold high nitrogen purity under various operating conditions guarantees the quality of the product as well as increases the shelf life.

Pharmaceutical Industry

Nitrogen is used in large quantities in pharmaceutical production, and it must be of high purity, this means that the supply should be consistent. PSA nitrogen generators are also capable of meeting the changing regulatory requirements and the diverse operating environments in the pharma industry to maintain the purity of the process.

Electronics and Semiconductor Manufacturing

In electronics and semiconductor manufacturing, PSA nitrogen generators ensure that the environment surrounding the manufacturing process is free from oxygen to prevent oxidation and contamination. This makes the generators quite adaptable to the prevailing environmental conditions hence the reliability and quality of the products

Chemical Processing

PSA nitrogen generators are widely applied for chemical processing for blanketing, purging, and inerting processes. The versatility of these systems in responding to changes in demand as well as differing operating conditions improves the safety and effectiveness of chemical plants.

Get in Touch with Absstem Today!

Contact Absstem today for the best PSA Nitrogen Plant. We are proud to offer state-of-the-art technology for producing high-purity nitrogen to your specifications. Avail the best of our services and get the benefits of efficiency, reliability, and cost-effective solutions. Get in touch with us today to take your operations to the next level with the highest-quality nitrogen generation.

Drop a line to get a quote or talk to an expert to get started with your on-demand, onsite installation of PSA oxygen generators. To find out more about our Oxygen Gas System Contact Us.

Conclusion

Industries that need a constant and pure supply of nitrogen must consider using PSA nitrogen generators. Its control systems, structural design, flexibility, integration of energy-efficient solutions, and remote-control features allow it to operate under various conditions. This flexibility not only guarantees high results but also saves a lot of money and improves operations. PSA nitrogen generators will, therefore, remain an essential part of the industries’ needs for nitrogen supply as industries change with time.

This paper has shown how PSA nitrogen generators are capable of modulating their performance depending on the prevailing operating conditions and how this information can be used by businesses to select a nitrogen generation solution that is capable of meeting their production needs reliably.

| Also Read: Why PSA Oxygen Generators Are Essential for Healthcare Facilities |