When considering a PSA (Pressure Swing Adsorption) Nitrogen Generator, several questions may come to mind:

What Does Nitrogen Purity Mean?

Why Do We Need Different Nitrogen Purities?

What is the Cost of Nitrogen Production at Different Purities?

In this blog, we will answer these questions in detail, helping you understand how PSA nitrogen generators work, how nitrogen purity is determined, and why certain applications require specific purity levels.

What is Nitrogen Purity?

A single PSA industrial nitrogen generator can produce nitrogen at varying purity levels depending on the specific needs of the application and corresponding flow rates. The purity typically ranges from 95% to 99.9995% in industrial applications, depending on how much oxygen and other trace gases remain in the nitrogen produced.

For example:

95% purity from PSA System means that the gas mixture contains 5% Oxygen and 95% Nitrogen and argon (along with trace amounts of other gases like CO₂, and CO).

99.9995% purity from PSA System (often referred to as ultra-high purity nitrogen) means that only 0.0005% or 5 PPM (parts per million) of oxygen is present in the gas.

Nitrogen purity is vital in determining the suitability of nitrogen for various industrial processes. The higher the purity, the fewer contaminants are present in the gas, making it more suitable for sensitive applications.

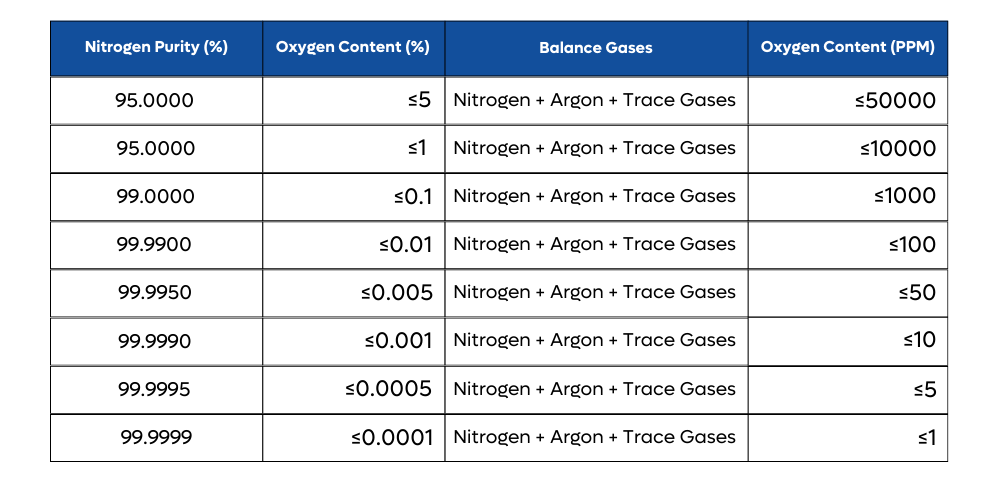

The following table gives a clear breakdown of nitrogen purity levels and their corresponding oxygen content

Why Do We Need Different Nitrogen Purities?

Different industries and processes require nitrogen with different purity levels depending on the specific requirements of the application. For instance:

Lower purity nitrogen (95-99%) is typically used for processes like inertization, purging, or blanketing, where the primary goal is to remove oxygen from the environment to prevent combustion or oxidation.

Ultra-high purity nitrogen (99.999%) is required for more sensitive applications such as laser cutting, heat treatment, and electronics manufacturing, where even trace amounts of oxygen can cause damage or defects in the final product.

The table below shows various industrial uses based on nitrogen purity:

Nitrogen Purity in Industry Applications

For example, food packaging often uses nitrogen with 99.9% purity, which is sufficient to prevent oxidation and maintain product freshness. In contrast, laser cutting requires nitrogen with at least 99.999% purity to achieve precise cuts without leaving burn marks or oxidation on the metal surface.

The flexibility of PSA technology allows you to produce nitrogen at various purities from a single system, unlike liquid or cylinder-based nitrogen supplies, which often offer only very high purities (99.9990-99.9998%).

What is the Cost of Nitrogen Production at Different Purities?

The cost of nitrogen production via PSA technology varies significantly as we move from lower to higher purity. This is mainly because producing higher-purity Nitrogen requires more energy ( High amount of compressed air ).

For example, generating nitrogen at 95% purity requires significantly less power than producing nitrogen at 99.999% purity, since removing the final traces of oxygen from the gas mixture is an energy-intensive process.

The table below shows how electricity consumption affects the cost of production of nitrogen at different purity levels, assuming the cost of electricity as ₹8/- per unit:

As the table shows, the power consumption—and consequently, the cost—increases as nitrogen purity rises.

For instance, producing nitrogen at 95% purity costs ₹1.76 per Nm³, whereas producing 99.9995% purity nitrogen costs ₹10.56 per Nm³. This significant difference highlights the need to carefully match the nitrogen purity level to the application requirements in order to optimize costs.

Conclusion

PSA nitrogen generators offer a cost-effective and flexible solution for businesses that require nitrogen for various applications. Unlike liquid nitrogen or nitrogen cylinders, PSA technology allows for on-site production of nitrogen at a range of purities, ensuring that the nitrogen generated is perfectly suited to your needs, whether it’s for purging, inertization, food packaging, or laser cutting.

By understanding nitrogen purity levels and their implications, businesses can optimize nitrogen production and ensure that their processes run efficiently and cost-effectively. PSA nitrogen generators not only reduce dependency on external suppliers but also provide significant savings in the long run.

If you’re considering upgrading your nitrogen supply system or need expert advice on selecting the right nitrogen purity for your application, don’t hesitate to contact us. Our team is here to help you make informed decisions and improve your operations. Reach out to us at [email protected] or call our toll-free number 1800 3010 3394.