PSA Oxygen Generator for Steel and Metal Industry: Enhance Efficiency & Quality

Absstem provides high-quality PSA oxygen generators across India, specifically designed for the steel and metal industry. These generators deliver a reliable supply of high-purity oxygen, improving processes like oxy-fuel cutting, welding, and furnace operations. By using Absstem, manufacturers can enhance efficiency, maintain consistent quality, and reduce reliance on external oxygen suppliers.

Steel and Metal Industry

Oxygen is used as a burning medium for the fuel to produce high temperature flame (termed as blue flame) and this process is called as oxy-fuel burning. The required flow of oxygen is decided based on the cutting torch design. These applications require consistent delivery of high purity oxygen at high pressure. The required oxygen pressure depends upon the steel grade type, block thickness (whether billet or bloom or wire) and the cutting cycle time for plants using automated lines with pre-set cutting time cycles.

How PSA Oxygen Generators Improve Steel and Metal Manufacturing

On-Site PSA oxygen generators provide a continuous supply of high-purity oxygen, enhance steel and metal production by providing on-demand oxygen that ensures cleaner combustion and precise temperature control. They help increase efficiency, ensure consistent product quality, and reduce dependence on bulk oxygen deliveries. With these generators, manufacturers can optimize operations while maintaining safety and cost-effectiveness.

Key Applications

Cutting

Oxygen and nitrogen are used as assist gases in laser or plasma cutting. They ensure precise cuts, minimal slag, and improved edge quality.

Welding

Nitrogen or oxygen creates a controlled atmosphere for welding. It reduces oxidation, enhances penetration, and improves weld strength.

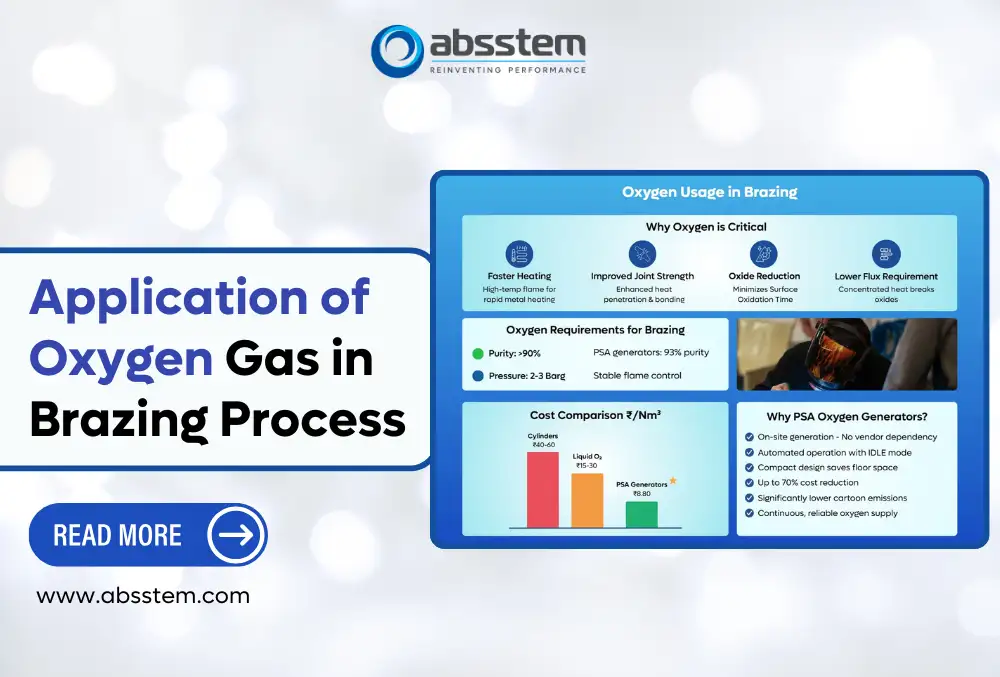

Brazing

An inert nitrogen atmosphere prevents oxidation during brazing. It produces clean joints and strong metallurgical bonds.

Challenges

Need for consistent delivery of high-purity oxygen

High-pressure oxygen supply requirements for oxy-fuel burning

Variable oxygen flow depending on cutting torch design and steel grade

Technical Data

| Purity Level | Pressure | Flow |

|---|---|---|

| Above 90% | 8-20 Barg | Contact Us |

Related Products

FAQs

How does PSA (pressure swing adsorption) oxygen improve steel making processes?

PSA (pressure swing adsorption) oxygen generators provide high-purity oxygen that accelerates chemical reactions in steel making, enhancing production speed, improving steel quality, and reducing fuel consumption.

How does oxygen help in metal cutting and welding operations?

High-purity oxygen from PSA generators ensures cleaner combustion, higher cutting temperatures, and precise welding, leading to improved efficiency and better product quality.

Can PSA oxygen generators be customized for different steel and metal applications?

Yes, they can be tailored to provide the required oxygen purity and flow rates for applications such as furnaces, converters, and cutting operations, ensuring optimal performance.

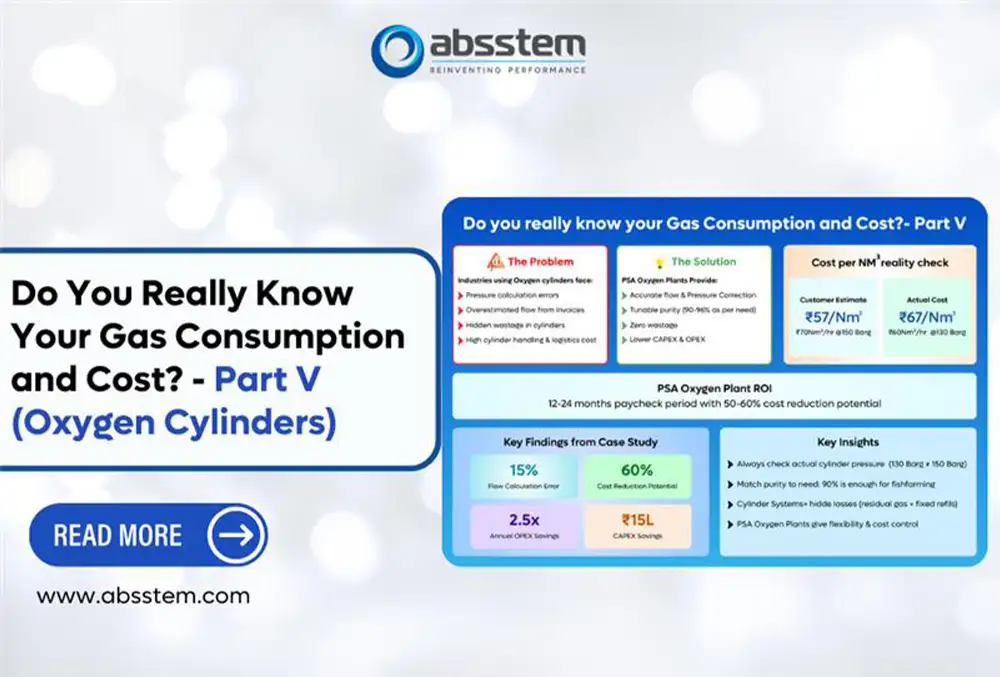

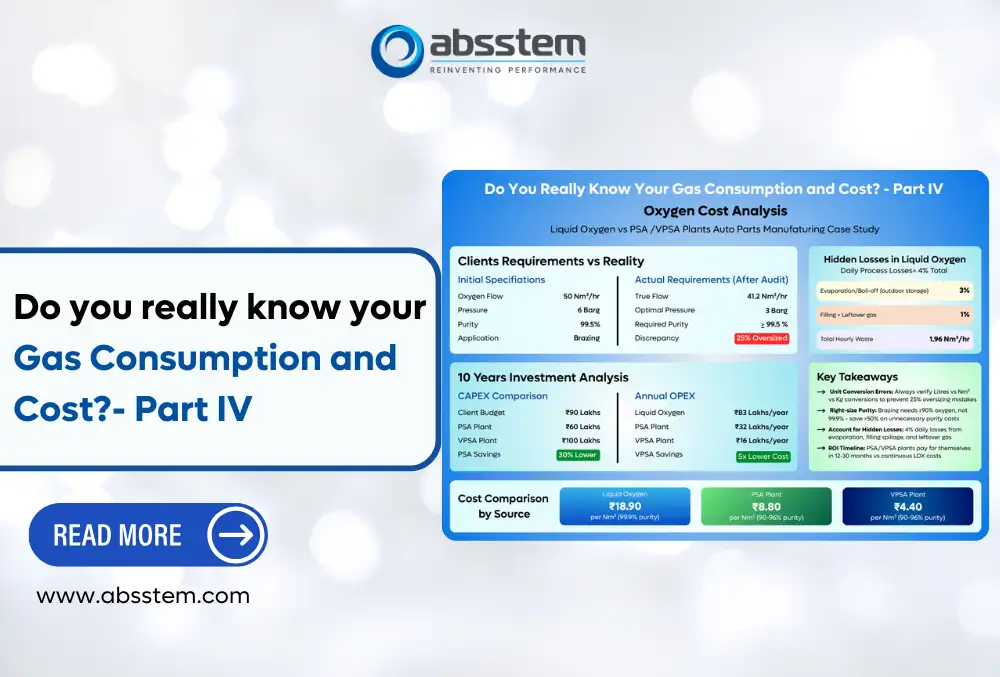

What cost savings can steel and metal manufacturers achieve with PSA oxygen generators?

On-site oxygen generation reduces dependence on bulk oxygen deliveries, cutting costs for purchase, storage, and transportation. ROI is typically realized within 1–2 years.

Are PSA oxygen generators suitable for all sizes of steel and metal operations?

Yes, they are scalable and can be configured for small, medium, or large industrial operations, providing consistent oxygen supply across different production volumes.

What environmental benefits do PSA oxygen generators offer to the steel and metal industry?

Using on-site PSA oxygen reduces transportation emissions, lowers energy consumption, and minimizes the carbon footprint of steel and metal production, promoting sustainability.

Blogs

Absstem Gallery

Trusted By Thousands

Request for Quote

For further information and tailored solutions, please contact us.