PSA Oxygen Generators can be very helpful for wastewater treatment today, as the scale of pollution & waste is increasing rapidly day by day. To control this, you should consider using PSA Oxygen Gas Generators

Imagine a life without oxygen and water. Do you believe that any creature can survive without these two essential resources? Most people aren’t even able to know about PSA oxygen Generators because they always ask questions like, “What are the oxygen generators?”, “How do we use it?” And we must educate them about the impact of Oxygen generators in wastewater treatment.

If you are among those who have these thoughts in their minds, then this blog is meant for you. In this blog, we are here as your partners to answer all your questions. So, without wasting time, let’s dive into this topic:

PSA oxygen generator is a device that makes oxygen. It takes in air from the environment and separates out the oxygen molecules, leaving behind other gases like nitrogen. This method, therefore, develops oxygen that can be used for distinct purposes including medical treatments, industrial applications, or in this case wastewater treatment. It can be said that it is the only machine that produces oxygen from the natural air.

Understanding Wastewater Treatment

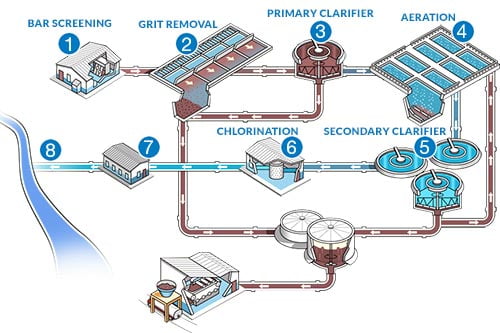

Before delving into the impact of oxygen generators, let’s begin by summarizing the basics of Oxygen Generator for Wastewater Treatment. The sewage with forms of pollutants and contaminants is treated by engineering processes to remove these impurities to gain its quality before it can be released into the environment. This is achieved by biological, chemical, and physical methods, which are focused on either completely excluding certain contaminants or diluting them to acceptable levels.

HOW DO PSA OXYGEN GENERATORS WORK?

Here is a Simple & Easy Procedure to Understand:

Air Intake: An oxygen generator is essentially like us, except it takes in air out of the environment, instead of breathing it from the environment it is in.

Separation Process: Inside the generator, air is separated into the elementary parts by using a special filter. This separates out the oxygen molecules from other gases like nitrogen and carbon dioxide.

Oxygen Concentration: After using the separation technique, oxygen is isolated. After that, it’s concentrated to make it purer and more useful in its targeted application. This means there’s a higher amount of oxygen compared to other gases.

Output: The concentrated oxygen is then released and can be used for various things, such as helping people breathe in hospitals or powering equipment in industries.

So, in a nutshell, oxygen PSA Generators take in air, separate the oxygen, concentrate it, and then provide it for different uses.

What is the Role of Oxygen in Wastewater Treatment

Oxygen plays a crucial role in wastewater treatment by promoting the growth of aerobic bacteria, which break down organic pollutants into harmless byproducts through biological processes. There are a few ways oxygen gets into wastewater. One common method is by bubbling oxygen through the water, similar to fish tank bubblers but on a larger scale. Another way is using PSA oxygen Generators, which produce oxygen on-site without the need for bulky oxygen tanks.

Advantages of having Absstem PSA oxygen gas-generators in the water treatment plant

India accounts for 2.45% of the land area and 4% of the water resources of the world but represents 16% of the world’s population. With the present population growth rate (1.9 percent per year), the population is expected to cross the 1.5 billion mark by 2050. The Planning Commission, Government of India has estimated the water demand increase from 710 BCM (Billion Cubic Meters) in 2010 to almost 1180 BCM in 2050 with domestic and industrial water consumption expected to increase almost 2.5 times. The trend of urbanization in India is exerting stress on civic authorities to provide basic requirements such as safe drinking water, sanitation, and infrastructure. The rapid growth of the population has exerted the portable water demand, which requires the exploration of raw water sources, and the development of treatment and distribution systems.

Implementation of Absstem PSA oxygen gas generators into water treatment plants offers numerous advantages.

They enhance the efficiency of biological treatment processes by supplying oxygen directly to aerobic bacteria, promoting faster and more effective breakdown of organic pollutants.

They provide a reliable and continuous supply of oxygen, eliminating external sources, which ensures uninterrupted treatment processes and minimizes the risk of oxygen shortages.

In contrast, relying on bulk delivery of oxygen can be accompanied by challenges in terms of complexity, cost and subject to potential supply chain disruptions.

Key benefits of having Absstem PSA Oxygen Gas Generators in a treatment plant:

Key benefits of incorporating Absstem PSA Oxygen Gas Generators into a treatment plant:

Reliability: Absstem PSA Oxygen Gas Generators provide our customers with a sustainable and uninterrupted oxygen supply with no risk of service delays or interruptions.

Cost: Absstem advanced oxygen generators significantly cut down on operational expenses by basically generating the required oxygen right on the site and without the need for purchasing liquid or compressed oxygen cylinders which have to be transported. This economical approach of course aids treatment plants in the planning of the budget and may ultimately incur sustained saving plans.

Control: Along with the Absstem Oxygen Gas Generators, the user can have full control over the gas production by being able to change the process output levels or tailor the specific process uses. Hence, the essence of using new technologies is to increase operational efficiency and ensure the proper functioning of the treatment plant.

Environment: By eliminating the need for transporting oxygen cylinders or relying on centralized oxygen production facilities, Absstem generators contribute to a reduction in carbon emissions and environmental impact. This sustainable approach aligns with the principles of eco-friendly operation and corporate responsibility.

Storage: Absstem PSA Oxygen Gas Generators replace the need for onsite oxygen storage tanks which provides tremendous area savings for oxygen transfer. With a slim footprint and the need for minimum logistics, the new storage system simplifies the operation and increases efficiency.

In general, Absstem Oxygen Gas Generators are associated with several advantages, such as the capacity to function continuously, cost-effectiveness, control, environmental friendliness, ease of storage, and significant safety.

Conclusion

Consequently, oxygen PSA generators demonstrate a revolutionary breakthrough in the field of wastewater treatment, having in this way a new effective, inexpensive, and environmentally friendly approach to aeration. The purity percentage of oxygen produced by a PSA (Pressure Swing Adsorption) generator for wastewater treatment typically ranges from 90% to 95%, providing cleaner water as far as water quality is concerned. In the face of this constant technological advancement, more and more PSA Oxygen generator systems are being developed. The inevitable will close in: These systems may just start the long journey of revamping the way we treat our precious water resources—a journey of multiple generations to redefine how we protect them.

| Also Read:- PSA Oxygen in the Environmental Remediation Industry: A Comprehensive Guide |

References: