Introduction

Pressure Swing Adsorption (PSA) systems are widely used to produce nitrogen and oxygen gas for various industrial applications. The unit economics of the production cost of nitrogen and oxygen gas are of utmost importance. Depending on crucial factors such as high-quality molecular sieves and optimized operation cycles, the role of storage tank volume is often overlooked.

This article explores the importance of selecting the appropriate storage tank size in PSA systems, focusing on its impact on operational costs, energy consumption, and capital investment.

Understanding PSA Systems and Gas Usage Patterns

Industries often do not require utility gases like nitrogen and oxygen at constant flow rates throughout the day. For example, some industries operate in shifts, requiring gas for only 8 to 16 hours per day. This variability in demand directly affects the efficiency of PSA systems. Traditional PSA systems, designed for constant output, can lead to wastage when the gas demand falls below the rated capacity. However, incorporating the correct storage tank volume allows for:

- Buffering Variable Flow Rates: Storing surplus gas during low-demand periods.

- Enhanced System Flexibility: Allowing on-off operation cycles to meet specific requirements.

Benefits of Optimized Storage Tank Volume

- 1. Reduction in Operational Costs

The correct storage tank size allows PSA systems to operate intermittently, saving energy during periods of low demand. For instance, systems with IDLE modes or economy modes can be turned off when the stored gas meets immediate needs. More on this can be found in our blog on Understanding Economy or Idle Mode in PSA Oxygen or Nitrogen Generators (1).

This on-off operation can significantly lower power consumption. - 2. Minimising Capital Investment

By selecting the right storage tank size, industries can avoid oversizing PSA systems. A well-designed storage tank compensates for peak demand periods, allowing smaller PSA units to handle larger peak loads. This reduces the initial capital required for PSA systems. - 3. Improved Gas Supply Stability

Storage tanks act as buffers, ensuring a stable supply of gas even during sudden surges in demand. This stability is critical for applications requiring consistent gas pressure and purity.

Case Study: Impact of Storage Tank Volume on PSA Systems

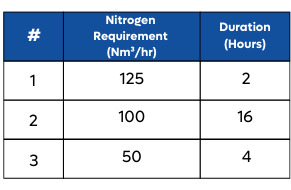

Scenario: A manufacturing plant requires nitrogen gas at 2 barg with the following demand pattern over a 24-hour period:

Approach 1: PSA System Sized for Maximum Demand

A PSA system with a capacity of 125 Nm³/hr and a standard 5000 L storage tank is installed. While this meets peak demand, it results in:

- Higher capital costs for the larger PSA system.

- Inefficient operation during periods of low demand.

Approach 2: PSA System with Optimized Storage Tank

A PSA system with a capacity of 100 Nm³/hr is paired with a 12,500 L storage tank. Nitrogen is produced at 6.5 barg, creating a 4 barg buffer (equivalent to 50 Nm³ of stored nitrogen. More on this can be found in our blog on Calculation of Volume of Gas stored in a High-Pressure Cylinder) (2). This setup:

- Meets the 125 Nm³/hr demand for 2 hours.

- Low power consumption during lower demand periods as the system enters IDLE mode.

- Requires a lower capital investment compared to the first approach.

For extended high-demand periods, such as 125 Nm³/hr for 3 hours, the storage tank size would need to increase to 20,000 L to maintain efficiency.

Practical Considerations

- Variable Demand Patterns: The required storage tank volume depends on the variability and duration of peak demand periods.

- System Design Parameters: PSA systems typically operate at pressures higher than end-use requirements (e.g., 6.5 barg vs. 2 barg). This pressure differential allows for effective storage and distribution.

- Impact of Machine Specifications: Consulting with machine manufacturers ensures that the selected storage tank volume aligns with equipment needs, avoiding overpressure or underperformance issues.

Conclusion

The selection of the right storage tank volume is a critical factor in optimizing the performance and economics of PSA systems. It not only reduces operational and capital costs but also ensures a stable and efficient gas supply. Industries should evaluate their specific gas usage patterns and consult with experts to determine the optimal storage tank size for their PSA systems.

Contact Us

For expert guidance on optimizing your PSA system and selecting the right storage tank volume, contact us at:

- Email: [email protected]

- Phone: 1800 3010 3394

Our team of experienced professionals is here to assist with tailored solutions for your industrial gas needs.

References

- Absstem Technologies. (2024). Understanding Economy or Idle Mode in PSA Oxygen or Nitrogen Generators.

- Absstem Technologies. (2024). Calculation of Volume of Gas Stored in a High-Pressure Cylinder.