In continuation of our previous blog How to Select the Right Nitrogen Plant for Varying Nitrogen Requirement: Part I (1), we now explore another real-world case study. Nitrogen requirement in industries does not remain constant throughout the day; it varies depending on production cycles, process steps, or operational demands. Selecting the right PSA nitrogen or oxygen plant in such scenarios becomes critical to avoid oversizing, reduce costs, and ensure an uninterrupted supply.

Case Study: Pharmaceutical Industry

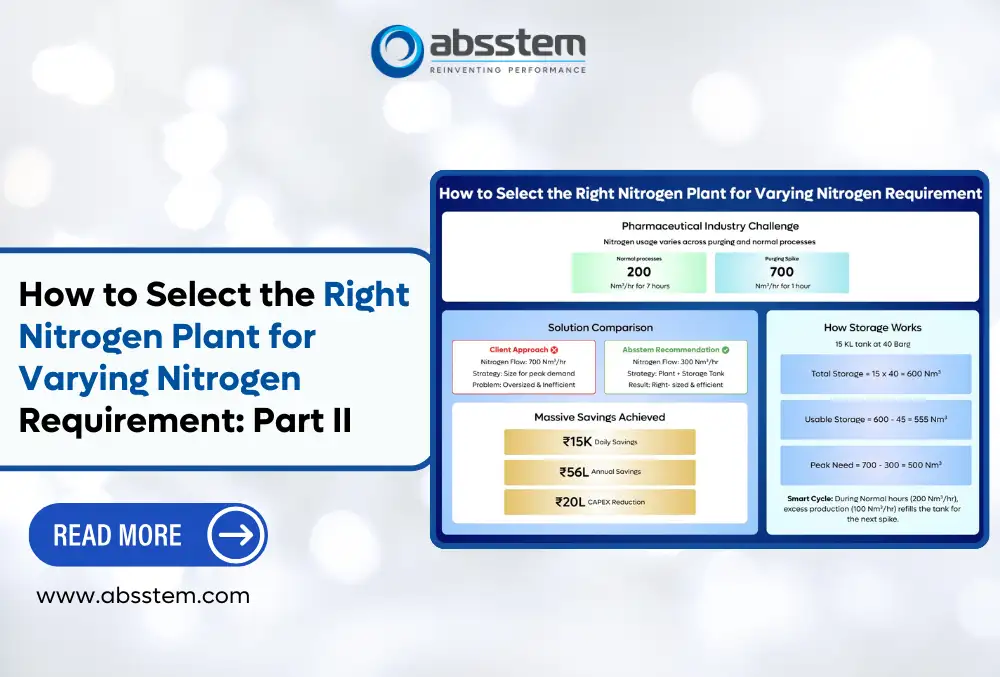

One of our pharmaceutical clients shared their nitrogen usage pattern, which fluctuated significantly over 24 hours. The following table summarises their nitrogen demand:

| Time | No. of Hours | Nitrogen Usage (Nm³/hr) | Remarks |

| 07:00–14:00 | 7 | 200 | Process requirements |

| 14:00–15:00 | 1 | 700 | Purging after batch production |

| 15:00–22:00 | 7 | 200 | Process requirements |

| 22:00–23:00 | 1 | 700 | Purging after batch production |

| 23:00–06:00 | 7 | 200 | Process requirements |

| 06:00–07:00 | 1 | 700 | Purging after batch production |

As observed, the nitrogen requirement suddenly spikes for 1 hour every 7 hours. This irregularity makes it challenging to select the right PSA nitrogen plant size.

Initial Client Selection

Based on the peak demand, the client initially opted for the following PSA nitrogen plant specifications:

- Nitrogen Flow: 700 Nm³/hr

- Pressure at Usage Point: 3 Barg

- Purity Required: 99.9%

While this sizing ensured peak demand coverage, it led to oversized equipment, high CAPEX, and significant operational costs due to continuous operation at maximum capacity.

Absstem’s Recommendation

After analysing the client’s demand cycle, we proposed a more optimised solution:

- Nitrogen Flow: 300 Nm³/hr

- Pressure at Usage Point: 3 Barg

- Purity Required: 99.9%

- Storage Tank Volume: 15 KL

- Storage Tank Pressure: 40 Barg

- Additional Equipment: Oil-free nitrogen compressor/booster for pressurising storage

This configuration allowed the plant to run efficiently at 300 Nm³/hr while handling sudden demand spikes using the stored nitrogen in the 15 KL, 40 Barg tank.

Corrected Nitrogen Requirement (After Absstem Visit)

| # | Parameter | Client Selection | Absstem Recommendation |

| 1 | Nitrogen Flow | 700 Nm³/hr | 300 Nm³/hr |

| 2 | Nitrogen Purity | 99.900% | 99.90% |

| 3 | Compressed Air Requirement | 1330 CFM | 570 CFM |

| 4 | Maintenance Cost | High | Low |

CAPEX & OPEX Savings

We further compared the cost impact between the client’s selection (600 Nm³/hr) and our recommendation (300 Nm³/hr):

| # | Parameter | Client Selection | Absstem Recommendation | Remarks |

| 1 | Nitrogen Flow | 700 Nm³/hr | 300 Nm³/hr | With 40 Barg booster |

| 2 | Nitrogen Purity | 99.900% | 99.90% | |

| 3 | Plant Cost | ₹130 Lacs | ₹110 Lacs | Capital savings of ~₹20 Lacs |

| 4 | Compressed Air Requirement | 1330 CFM | 570 CFM | |

| 5 | Compressor kW | 225 kW | 145 kW | (90 kW + 55 kW for booster) |

| 6 | Daily Operating Cost (Power) | ₹43,200 | ₹27,840 | At ₹8/unit electricity cost |

Result:

- Daily savings: ~₹15,000/-

- Annual savings: ~₹56 Lakhs

- CAPEX reduction: ~₹20 Lakhs

This demonstrates how correct sizing + storage integration drastically reduces both upfront and operational expenses.

How Was This Saving Achieved?

To ensure an uninterrupted nitrogen supply during peak demand, storage plays a vital role.

Technical Insight: How Storage Meets Peak Demand

Gas Storage Formula:

Volume of gas stored in a tank = Tank Volume (Water holding capacity) × Pressure (Absolute)

For a 15 KL tank at 40 Barg:

- Total stored nitrogen = 15 × 40 = 600 Nm³

- Non-usable nitrogen (below 3 Barg) = 15 × 3 = 45 Nm³

- Usable nitrogen = 600 – 45 = 555 Nm³

Requirement:

- Extra nitrogen needed during peak = (700 – 300) = 500 Nm³

- Available stored nitrogen = 555 Nm³

- Tank pressure drops from 40 Barg to ~7 Barg after the peak hour.

From 15:00 onwards, the nitrogen demand decreases to 200 Nm³/hr for the next 7 hours. During this period, the surplus production from the nitrogen plant (300 – 200 = 100 Nm³/hr) is stored in the tank, gradually raising the pressure back to 40 Barg.

At 22:00 – 23:00, an additional demand arises for 1 hour, once again supplied from the tank, which lowers the tank pressure back to 7 Barg.

Following this, the consumption reduces again to 200 Nm³/hr for another 7 hours, allowing the excess nitrogen produced (100 Nm³/hr) to be stored in the tank until the pressure again reaches 40 Barg.

This cycle continues repetitively, balancing production, storage, and usage.

Optimised Nitrogen Cycle with 15 KL storage tank and 300 Nm3/hr nitrogen plant

| Time | No. of Hours | Nitrogen Usage (Nm³/hr) | Remarks | Storage Tank Pressure | Storage/Usage |

| 07:00 – 14:00 | 7 | 200 | Process requirements | 40 Barg at 14:00 | 100 Nm³/hr stored in tank |

| 14:00 – 15:00 | 1 | 700 | Purging after batch | 7 Barg at 15:00 | 500 Nm³ used from tank |

| 15:00 – 22:00 | 7 | 200 | Process requirements | 40 Barg at 22:00 | 100 Nm³/hr stored in tank |

| 22:00 – 23:00 | 1 | 700 | Purging after batch | 7 Barg at 23:00 | 500 Nm³ used from tank |

| 23:00 – 06:00 | 7 | 200 | Process requirements | 40 Barg at 06:00 | 100 Nm³/hr stored in tank |

| 06:00 – 07:00 | 1 | 700 | Purging after batch | 7 Barg at 07:00 | 500 Nm³ used from tank |

This cycle ensures that the plant continuously operates at optimal efficiency, while storage tanks compensate for sudden peaks.

Conclusion

This case study highlights why selecting the right PSA nitrogen plant is not just about matching peak demand; it requires careful demand pattern analysis, storage integration, and system optimisation.

With the right design, pharmaceutical companies (and other industries) can save significantly on both capital investments and yearly operational costs while ensuring uninterrupted nitrogen supply.

Consult Us

If you need help selecting the right size of Nitrogen plant for your application, please contact us:

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: absstem.com

References

- Absstem Technologies. (2025). How to Select the Right Nitrogen Plant for Varying Nitrogen Requirement: Part I