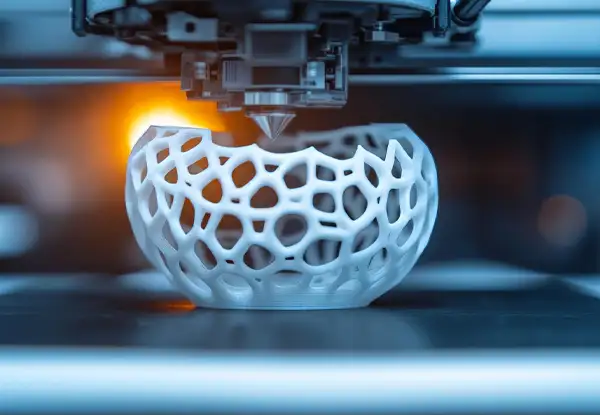

Efficient Nitrogen Generator for 3D Printing Using PSA Technology

Absstem provides advanced PSA nitrogen generators across India, designed to meet the controlled-atmosphere requirements of the 3D printing and additive manufacturing industry. Our systems deliver a continuous, cost-effective supply of high-purity nitrogen to improve print quality, prevent oxidation, and ensure repeatable, high-precision manufacturing.

Why PSA Nitrogen Generators Are Essential for 3D Printing

Additive manufacturing requires controlled, uninterrupted nitrogen supply with consistent purity. Absstem’s PSA nitrogen generators provide reliable on-site nitrogen generation, eliminating dependence on cylinders and ensuring uninterrupted printing operations.

By maintaining a low-oxygen atmosphere, PSA nitrogen systems help improve surface finish, dimensional accuracy, and mechanical strength of printed components while reducing scrap rates and post-processing requirements.

Key Applications

Nitrogen Inerting

Nitrogen is used to displace oxygen inside the 3D printer build chamber, preventing oxidation of molten metal or polymer during printing.

Metal Powder Protection

Nitrogen protects metal powders from oxidation during printing, powder handling, recycling, and storage.

Laser Sintering & Melting Processes

Processes such as SLS, DMLS, and SLM rely on nitrogen to maintain process stability and consistent layer fusion.

Post-Processing & Cooling

Nitrogen is used during controlled cooling and post-processing to avoid oxidation and discoloration of finished parts.

Challenges

Oxidation During Printing

Presence of oxygen leads to poor surface finish, weak layer bonding, and reduced part strength.

Moisture Sensitivity

Moisture affects powder flowability and print consistency, especially in polymer and metal powder systems.

Cylinder Dependency

Nitrogen cylinders cause supply interruptions, inconsistent purity, and high operating costs.

Process Consistency

Fluctuations in nitrogen purity or availability directly impact print repeatability and quality.

Technical Data

| Application | Recommended Nitrogen Purity (%) | Recommended Nitrogen Flow | Recommended Nitrogen Pressure (Barg) |

|---|---|---|---|

| Inerting | 99 – 99.9% | Contact Us | Up to 6 |

| Metal Powder Protection | 99 – 99.9% | Contact Us | Up to 6 |

| Laser Sintering / Melting | 99 – 99.9% | Contact Us | Up to 6 |

| Post-Processing / Cooling | 95 – 99.9% | Contact Us | Up to 6 |

Note: Oxygen concentration inside the build chamber is often maintained below critical ppm levels depending on material and process.

Related Products

FAQs

Why is nitrogen required in 3D printing?

Nitrogen is required in 3D printing to prevent oxidation and moisture contamination inside the build chamber, ensuring better surface finish, stronger mechanical properties, and consistent print quality in additive manufacturing processes.

What nitrogen purity is required for additive manufacturing?

Most additive manufacturing and 3D printing applications require nitrogen purity between 99% and 99.9%. Certain metal 3D printing processes may require higher purity depending on material and process sensitivity.

Is PSA nitrogen suitable for continuous 3D printing operations?

Yes. PSA nitrogen generators are well suited for continuous and batch 3D printing operations, providing a reliable, uninterrupted supply of nitrogen with consistent purity.

Can one PSA nitrogen generator supply multiple 3D printers?

Yes. A centralized PSA nitrogen system can supply nitrogen to multiple 3D printers, build chambers, and post-processing stations within an additive manufacturing facility.

How does on-site nitrogen generation reduce operating costs in 3D printing?

On-site nitrogen generation eliminates dependence on cylinders, reduces supply interruptions, minimizes downtime, and lowers long-term operating costs for 3D printing operations.

Blogs

Absstem Gallery

Trusted By Thousands

Request for Quote

For further information and tailored solutions, please contact us.