nGEN – Industrial Nitrogen Generator for On-Site PSA Nitrogen Production

Absstem’s nGEN Industrial Nitrogen Generator is a PSA-based on-site nitrogen generation system built for manufacturing plants that require continuous, high-purity nitrogen without cylinder or liquid nitrogen dependency. Unlike packaged machines, nGEN is delivered as a fully engineered, installed, and commissioned PSA nitrogen system that supplies nitrogen directly to your production lines at the required purity, pressure, and flow. It is trusted across food processing, pharmaceuticals, Semiconductor, electronics, metal fabrication, laser cutting, tyre manufacturing, oil and gas, power plants, 3D printing, and chemical industries where nitrogen quality and uptime directly impact product performance and cost.

What is an Industrial Nitrogen Generator?

An industrial nitrogen generator is a system that produces nitrogen on-site from atmospheric air using Pressure Swing Adsorption (PSA) technology. It replaces cylinders and liquid nitrogen by delivering continuous, on-demand nitrogen directly to the plant.

nGEN is Absstem’s industrial-grade PSA nitrogen generator, designed for 24×7 manufacturing environments.

How PSA Nitrogen Generator Works

Air Intake & Purification

Ambient air is filtered, dried, and compressed to remove moisture, dust, and oil.

PSA Nitrogen Separation

Carbon molecular sieves adsorb oxygen while allowing nitrogen to pass through.

Nitrogen Storage & Delivery

Nitrogen is stored in buffer tanks and supplied to your process pipelines.

Automated Control

PLC-based automation with IIoT monitoring ensures stable purity and low operating cost.

Typical Performance of PSA Nitrogen Plant

| Parameter | nGEN Capability |

|---|---|

| Nitrogen Purity | 95% to 99.9995% |

| Nitrogen Flow | Up to 3000 Nm³/hr |

| Delivery Pressure | Up to 350 kg/cm²g (with booster compressors) |

| Operation | Continuous 24×7 |

| Monitoring | IIoT-enabled remote access |

Delivered as a Complete On-Site Nitrogen System

nGEN is supplied as a fully integrated PSA nitrogen generation system, not as standalone equipment. Each system includes:

PSA nitrogen generator modules

Air compressors, dryers, and filtration

Nitrogen storage tanks and safety systems

HD touchscreen HMI

On-site installation & commissioning

Operator training, & long-term AMC and CMC through Absstem Shield

Why Industrial Plants Choose PSA Nitrogen Generator

Lowest Cost of Nitrogen Production

Optimised air-to-gas ratios and energy-efficient PSA cycles deliver the lowest cost per Nm³ of nitrogen compared to cylinders or bulk liquid nitrogen

Stable Purity for Process Reliability

nGEN maintains consistent nitrogen purity, pressure, and flow, even during fluctuating production loads

No Cylinder or Cryogenic Logistics

Cylinder handling. Storage risks. Transport delays. Vendor dependency

Designed for Continuous Manufacturing

Built for 24×7 industrial duty cycles with minimal downtime

Technology & Reliability of On-Site PSA Nitrogen Plant

10-year molecular sieve performance warranty

IIoT-enabled monitoring & alerts

Automatic idle mode with auto start/stop

Industrial-grade HD touchscreen HMI

AMCs and CMCs by Absstem Shield for continuous uptime

Industries Using On-Site Industrial Nitrogen Generator

Oil & Gas

Support pipeline purging, pressure testing, tank blanketing, and shutdown maintenance with continuous on-site nitrogen without cylinder logistics.

Metal Processing & Heat Treatment

Use nitrogen for annealing, sintering, brazing, and heat treatment to prevent oxidation and achieve consistent surface finish and strength.

Chemical Industry

Provide reliable nitrogen for purging, blanketing, and inerting to enhance plant safety, prevent reactions, and ensure stable chemical processing.

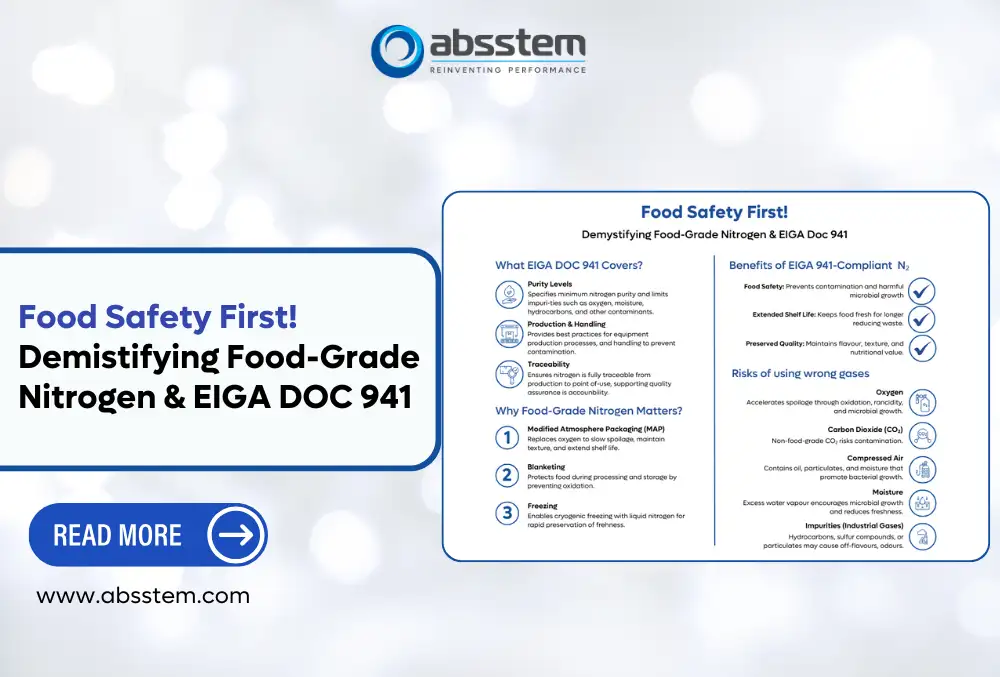

Food & Beverage Packaging

Ensure longer shelf life, prevent oxidation, and maintain taste, texture, and quality with continuous nitrogen supply for MAP, nitrogen flushing, and packaging operations.

Pharmaceuticals

Maintain contamination-free environments with ultra-high purity nitrogen for blanketing, drying, packaging, and cleanroom manufacturing applications.

Tyre Manufacturing

Improve tyre curing, inflation stability, and product consistency using clean, dry nitrogen while reducing moisture-related defects.

Laser Cutting & Fabrication

Achieve burr-free edges, oxidation-free surfaces, and superior cutting performance with high-pressure nitrogen assist gas directly from your plant.

Electronics & Semiconductor Assembly

Protect sensitive components during soldering, reflow, and assembly with controlled nitrogen atmospheres for improved yield and reliability.

Power Plants

Use nitrogen for boiler preservation, inerting, and purging to protect critical equipment, reduce corrosion, and improve plant reliability.

3D Printing

Maintain oxygen-free environments in metal 3D printing processes to enhance part quality, strength, and repeatability.

Explore More Nitrogen & Oxygen Solutions

Advanced PSA technology based medical oxygen systems for hospitals, clinics, and healthcare sectors.

Tailor-made PSA oxygen generator designed for hospitals and nursing homes with specific capacity or layout needs.

High-efficiency PSA oxygen generator for manufacturing, aquaculture, and other process industries.

Affordable, high-performance oxygen systems built for SMEs, MSMEs, and OEMs requiring steady on-site supply.

Space-saving, plug-and-play nitrogen generator ideal for food packaging, electronics, and pharma applications.

Absstem’s all-inclusive AMC ensuring 24×7 uptime, preventive care, and remote support for oxygen and nitrogen systems.

Trusted By Thousands

FAQs – nGEN (Industrial Nitrogen Generator)

Is nGEN a nitrogen generator or a nitrogen plant?

nGEN is a PSA nitrogen generator delivered as a complete on-site nitrogen plant. It includes air compressors, PSA nitrogen generation modules, storage tanks, controls, installation, and commissioning. At Absstem, nGEN is supplied as a fully engineered nitrogen system, not just standalone equipment.

How does a PSA nitrogen generator work?

A PSA nitrogen generator works by separating nitrogen from compressed atmospheric air using carbon molecular sieves. Oxygen and trace gases are adsorbed, while nitrogen passes through and is collected in storage tanks. The system operates automatically in cycles to deliver continuous, on-site nitrogen at the required purity, pressure, and flow for industrial processes.

Can nGEN replace nitrogen cylinders and liquid nitrogen completely?

Yes. nGEN is designed to act as the primary nitrogen source for industrial operations. It eliminates cylinder handling, refilling delays, storage risks, and dependence on external nitrogen suppliers while providing uninterrupted 24×7 nitrogen supply.

What nitrogen purity and flow can nGEN deliver?

nGEN can deliver nitrogen purity from 95% up to 99.9995%, with flow capacities up to 3000 Nm³/hr, depending on the application. The system is engineered based on actual process demand to ensure stable purity, pressure, and flow.

Which industries are best suited for nGEN industrial nitrogen generators?

nGEN industrial nitrogen generator is widely used in food processing, pharmaceuticals, electronics, semiconductor manufacturing, metal fabrication, laser cutting, chemical plants, oil & gas, power plants, and tyre manufacturing-where nitrogen quality, uptime, and cost control are critical.

How is nGEN different from compact or packaged nitrogen generators?

Unlike packaged nitrogen generators, nGEN is delivered as a fully installed and commissioned PSA nitrogen system. It is designed for continuous industrial duty, higher flow rates, scalable capacity, and long-term reliability, making it suitable for large manufacturing plants rather than intermittent or small-scale use.

Blogs

Request for Quote

For further information and tailored solutions, please contact us.