Nitrogen is an essential industrial gas used extensively in electronics, food preservation, and chemical manufacturing. Traditional methods of nitrogen production, such as Pressure Swing Adsorption (PSA), face challenges regarding efficiency and resource utilization. This article explores potential advancements in nitrogen production through adsorption, focusing on enhancing recovery, reducing wastage, and developing cost-efficient systems.

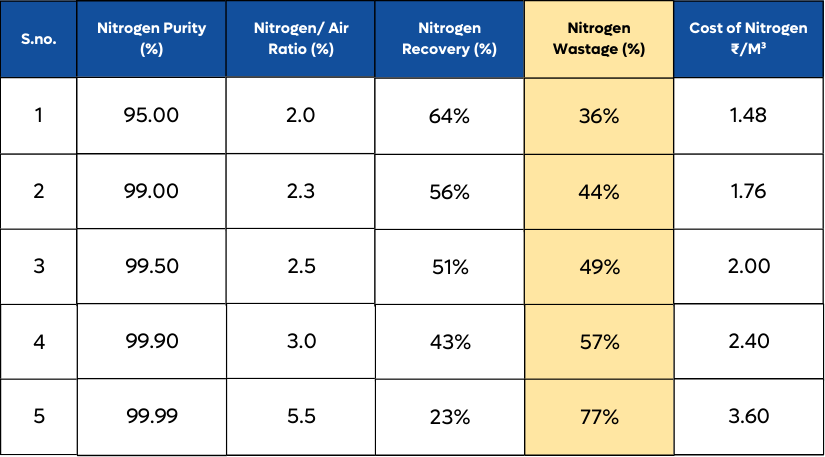

The table below highlights the current parameters and performance outcomes of nitrogen generation via PSA:

As shown in the table above, current PSA processes result in the wastage of nearly 40% of nitrogen, which cannot be recovered. Additionally, almost 100% of the oxygen is also lost during the process.

Challenges in Current PSA Processes

- High Wastage Rates

Approximately 40% of nitrogen is wasted in typical PSA processes. Additionally, nearly 100% of oxygen is vented into the atmosphere, representing significant inefficiencies in resource utilization. - Rising Costs

The cost of nitrogen production escalates with purity. For instance, achieving 99.99% purity incurs a cost more than double that of 95% purity due to higher nitrogen/air ratios and energy requirements. - Energy Consumption

PSA systems are energy-intensive, requiring significant power input to compress air and regenerate adsorbents.

Advancements in PSA Nitrogen Production

- Increasing Nitrogen Recovery

Using multiple adsorbers in series is a promising solution. The recovery rate can be significantly improved by redirecting the waste stream from one adsorber as feed for another. This approach minimizes nitrogen losses and enhances overall system efficiency.

Potential Benefits- Higher nitrogen yield per cycle.

- Reduced dependence on air compression, lowering operational costs.

- Dual-Product Systems: Oxygen and Nitrogen

Vent oxygen from nitrogen production can be captured and separated, creating a dual-product system. This approach improves the economic viability of PSA technology by providing both gases from a single plant.

Key Innovations- Selective adsorbents for oxygen separation.

- Modified operational cycles to accommodate dual recovery.

- Advanced Adsorbents:

Research into novel adsorbent materials is vital for improving adsorption rates and efficiency. Promising directions include:- Tailored pore distributions: Ensuring adsorbents selectively target nitrogen molecules.

- Nanomaterials and composites: Synthetically engineered materials that enhance adsorption capacity and cycle durability.

Current Developments

- Zeolites with optimized frameworks for specific gas separations.

- Carbon-based materials, such as activated carbons and carbon molecular sieves, with superior selectivity.

Impact of These Advancements

- Reduction in Production Costs

As seen in the table, the cost of nitrogen production varies with purity and recovery rates. Integrating advanced recovery methods and adsorbents could reduce costs by up to 50%. For example:- Current cost of nitrogen (95% purity): ₹1.48/m³.

- Estimated cost with advanced recovery: ₹0.74/m³.

- Power Efficiency

Efficient systems producing nitrogen and oxygen simultaneously will optimize the energy-per-unit-gas ratio. This reduces the environmental impact and aligns with global sustainability goals. - Wider Adoption of PSA Technology

By addressing inefficiencies, PSA systems can expand into applications where high purity and multi-gas recovery are essential.

The Future of PSA in Gas Separation

To rival traditional methods like fractional distillation, PSA systems must evolve to separate multiple gas streams effectively. Innovations such as multi-adsorbent beds and automated process controls could pave the way for PSA-based separation of argon, carbon dioxide, and other gases alongside nitrogen and oxygen.

Vision for PSA Technology

Future PSA systems may feature:

- Integrated sensors and AI for real-time process optimization.

- Modular designs for scalability and customization.

- Enhanced durability of adsorbents, reducing maintenance frequency.

Conclusion

Advancements in adsorption technology hold immense promise for transforming nitrogen production. The PSA process can become a cornerstone of sustainable gas separation by addressing current inefficiencies. Efforts to enhance recovery rates, integrate oxygen separation, and develop novel adsorbents will drive this transition.

At Absstem, we are committed to innovating adsorption technology to meet the demands of tomorrow. Our research focuses on achieving complete gas separation with minimal wastage, ensuring that PSA systems remain at the forefront of industrial gas production.

Contact Us

If you’re looking to optimize nitrogen production, explore cutting-edge adsorption technologies, or seek tailored PSA solutions, our team at Absstem is here to assist. We bring expertise, innovation, and a commitment to advancing gas separation technologies.

Email: [email protected]

Toll-Free: 1800 3010 3394

References:

- AIChE. (2012). Producing Nitrogen via Pressure Swing Adsorption

- AIP Conference Proceedings. (2022). A short review of pressure swing adsorption (PSA) technology for nitrogen generation from air

- MDPI. (2020). Material Development for Enhanced PSA Systems