Nitrogen is an essential gas used in various industries, and its applications often depend on the pressure at which it is supplied. In this article, we will delve into the different pressures required for various industrial uses of nitrogen, highlighting the technical considerations and implications of these requirements.

This discussion builds upon our previous blog about nitrogen purity in different applications, which you can read here (1).

Overview of Nitrogen Production via PSA

Pressure Swing Adsorption (PSA) is a highly economical method for nitrogen production. Typically, nitrogen is generated at a standard pressure of 6.5 Barg. However, specific applications may require significantly lower or higher pressures, ranging from 0.1 Barg to as much as 300 Barg. For pressures above 13 Barg, nitrogen boosters are employed to achieve the desired levels efficiently.

Importance of Optimal Pressure

Using nitrogen at pressures below the required levels can compromise the quality and efficiency of processes. Conversely, using higher-than-necessary pressure leads to unnecessary energy consumption and operational costs. Therefore, determining the optimal nitrogen pressure for each application is critical. Consulting with equipment manufacturers or nitrogen system experts is recommended to ensure proper specifications.

Nitrogen Pressure Requirements for Different Applications

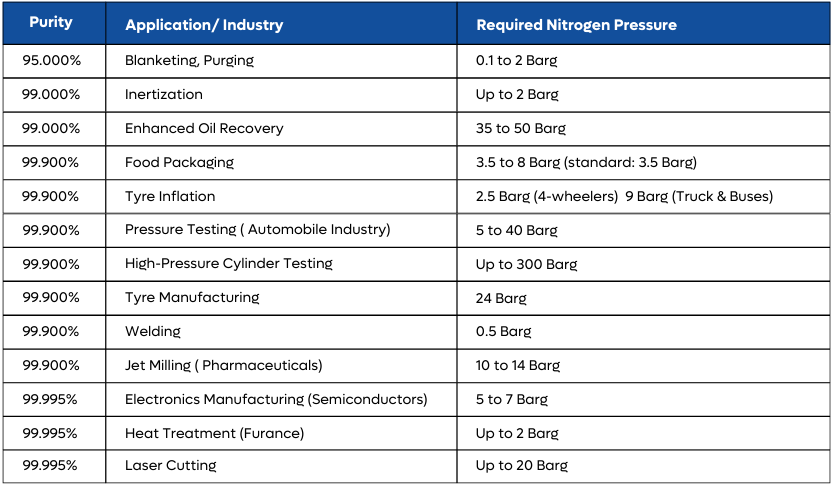

The table below outlines the typical nitrogen pressure requirements across various industries and applications:

Applications in Focus

-

1. Food Packaging

Food packaging processes have traditionally utilised nitrogen at around 3.5 Barg. However, advancements in packaging technology have led to increased pressure requirements, with some modern packing systems operating at pressures of 7 to 8 Barg.

-

2. Enhanced Oil Recovery (EOR)

Enhanced Oil Recovery involves injecting nitrogen at high pressures, typically ranging from 35 to 50 Barg, into oil wells to increase extraction efficiency. The high pressure helps reduce the viscosity of the oil, making it easier to extract. This application demands robust nitrogen delivery systems capable of maintaining consistent pressure.

-

3. Semiconductor Manufacturing

In electronics manufacturing, nitrogen of 99.995% purity is used to create inert environments, ensuring product integrity. The pressure requirements, typically 5 to 7 Barg, ensure effective nitrogen flow for processes such as soldering and chip production.

-

4. Laser Cutting

Laser cutting relies on high-purity nitrogen (99.999%) to achieve precise cuts without oxidation. The required pressure, up to 20 Barg, ensures a consistent flow that supports high-speed cutting and minimizes contamination of the cut surfaces

-

5. Tyre Manufacturing and Inflation

For tyre manufacturing, nitrogen at 99.99% purity and 24 Barg is essential to create the right conditions for vulcanization. For tyre inflation, the pressure requirement is much lower, at around 2.5 Barg for 4-wheelers and 9 barg for commercial vehicles like trucks etc., ensuring better performance and longevity compared to air-filled tyres

-

6. High-Pressure Cylinder Testing

Testing high-pressure cylinders requires nitrogen pressures of up to 300 Barg. This application emphasizes the critical role of nitrogen boosters, which are designed to handle extreme pressures safely and efficiently.

Technological Advancements and Evolving Requirements

With ongoing innovations in industrial machinery and processes, nitrogen pressure requirements are continually evolving. For example, next-generation food packaging machines demand higher pressures than traditional systems. Similarly, advancements in welding and heat treatment technologies are driving changes in nitrogen usage parameters.

Energy Efficiency Considerations

The power consumption of nitrogen production increases with pressure. For pressures beyond the standard 6.5 Barg, PSA plants need to work harder, consuming more energy. Nitrogen boosters, though efficient, also add to energy demands. Therefore, industries must carefully balance pressure requirements with energy costs to maintain sustainable operations.

Conclusion

Nitrogen pressure requirements vary significantly across industries, influenced by application-specific demands and technological advancements. Optimizing nitrogen pressure not only enhances process efficiency but also minimizes energy wastage and operational costs. As industrial needs evolve, staying updated with the latest nitrogen usage trends is vital for maintaining a competitive edge.

Contact Us

If you require assistance in determining the right nitrogen pressure and purity for your application, our experienced team is here to help. Reach out to us at [email protected] or call our toll-free number 1800 3010 3394 for expert guidance.

References

- Absstem Technologies. (2024). Understanding Nitrogen Purity in PSA Nitrogen Generators