Tire pyrolysis is an advanced recycling process that converts end-of-life tires into valuable products such as pyrolysis oil, carbon black (char), and gases. A crucial element in this process is Nitrogen gas, which ensures safe, efficient, and controlled operations.

In this blog, we will explore the most common questions about the application of Nitrogen gas in tire pyrolysis, its role, purity levels, cost considerations, and why PSA Nitrogen Generators are emerging as the preferred solution.

Where is Nitrogen used in Tire pyrolysis?

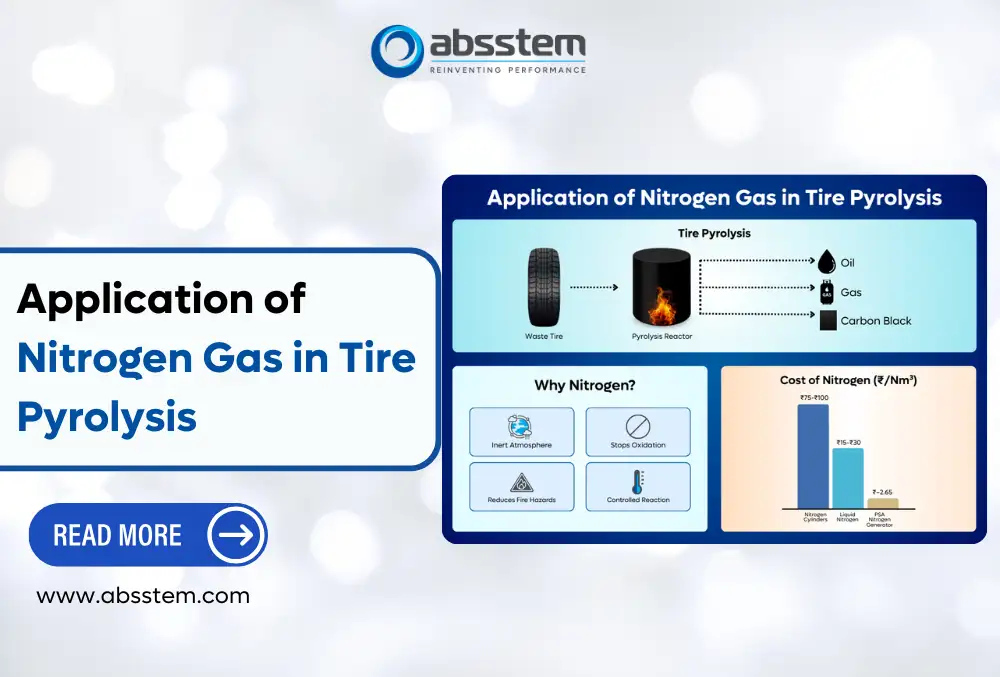

Tire pyrolysis involves the thermal decomposition of waste tires (to manufacture products like oil, char, etc.) in the temperature range of 300-900°C. Since the process takes place in an oxygen-free environment, Nitrogen gas has multiple benefits:

- Inert Atmosphere – Nitrogen displaces air (oxygen) inside the reactor, preventing ignition of tire material.

- Stops Oxidation – By eliminating oxygen, it prevents oxidation of end-products like oil and char, improving yield quality.

- Better Heat Transfer – Nitrogen enhances heat distribution inside the reactor, ensuring consistent pyrolysis.

- Controlled Reaction – An inert Nitrogen environment prevents unwanted side reactions that could otherwise occur in the presence of oxygen.

- Reduces Fire Hazards – Removal of oxygen significantly lowers the risk of fire or explosions.

Apart from Nitrogen, can we use other inert gases?

The right answer is yes. Theoretically, inert gases like argon and helium can also be used. The differences lie in the cost of production of these gases.

Cost of production of Nitrogen ~ 100 times < Cost of production of Argon

Cost of production of Nitrogen ~ 1000 times < Cost of production of Helium

Therefore, Nitrogen becomes the best solution. The reason for the low cost of production of nitrogen is the availability of abundant nitrogen (78%) in the atmosphere.

To understand more about the cost of production of nitrogen via PSA nitrogen generators, please read our blog titled, Understanding Nitrogen Purity in PSA Nitrogen Generators.

What is the purity of Nitrogen required in Tire Pyrolysis?

The purity of nitrogen gas in Tyre pyrolysis varies between 99.5 to 99.9%, where these purities of nitrogen signify the oxygen content in nitrogen.

To get more clarity about the purity of nitrogen gas, please read our blog titled, Understanding Nitrogen Purity in PSA Nitrogen Generators .

How much Nitrogen is required?

The volume of Nitrogen depends on:

- Reactor size

- Process design

It is always recommended to consult the OEM (Original Equipment Manufacturer) of the pyrolysis reactor before finalising Nitrogen requirements.

What is the Nitrogen pressure required in Tire Pyrolysis?

Nitrogen at a pressure of 1- 2 Barg is required in the Tire pyrolysis process.

What are the different sources of nitrogen for Tire Pyrolysis?

Traditionally, industries relied on liquid Nitrogen tanks or cylinders. However, with advancements in PSA (Pressure Swing Adsorption) technology, on-site Nitrogen generation has become the most efficient and cost-effective option.

The cost of nitrogen reduces drastically when produced via a PSA nitrogen generator. The table below shows the cost of Nitrogen from different sources:

Cost Comparison of Nitrogen Sources

| Source | Cost per Nm³ (₹) |

| Nitrogen Cylinders | 75-100 |

| Liquid Nitrogen | 15-30 |

| PSA Nitrogen Generator | ~2.65 |

To read more about the cost of different sources of nitrogen, please read our blog titled, How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders.

Can high-purity nitrogen of 99.99 or 99.999% be used in Tire pyrolysis?

In most cases, 99.5-99.9% pure nitrogen gas is used in Tire pyrolysis. This will cost around ₹2.6/- per cubic meter when produced through a PSA Nitrogen Generator.

The cost of nitrogen production via PSA technology varies significantly as we move from lower to higher purity. This is mainly because producing higher-purity Nitrogen requires more energy (High amount of compressed air).

For example, generating nitrogen at 95% purity requires significantly less power than producing nitrogen at 99.9990% purity, since removing the final traces of oxygen from the gas mixture is an energy-intensive process.

The table below shows how electricity consumption affects the cost of production of nitrogen at different purity levels, assuming the cost of electricity as ₹8/- per unit, as per our blog titled, Understanding Nitrogen Purity in PSA Nitrogen Generators .

Cost of Nitrogen Production at Different Purities via PSA Generators

| Nitrogen Purity | Power Consumption (kW/Nm³) | Cost of Nitrogen per Nm3/hr (₹) |

| 95.0000% | 0.22 | 1.76 |

| 99.0000% | 0.30 | 2.40 |

| 99.9000% | 0.33 | 2.64 |

| 99.9900% | 0.60 | 4.80 |

| 99.9950% | 0.80 | 6.40 |

| 99.9990% | 1.06 | 8.48 |

| 99.9995% | 1.32 | 10.56 |

As the table shows, the power consumption, and consequently, the cost, increase as nitrogen purity rises.

Higher purity = Higher electricity consumption = Higher cost

For instance, producing nitrogen at 95% purity costs ₹1.76 per Nm³, whereas producing 99.9995% purity nitrogen costs ₹10.56 per Nm³. This significant difference highlights the need to carefully match the nitrogen purity level to the application requirements to optimise costs.

Why PSA Nitrogen Generators are the preferred choice in Tire Pyrolysis?

Compared to the traditional sources of nitrogen gas like cylinders or liquid tanks, PSA nitrogen generators are far more beneficial in Tire Pyrolysis. Below are the benefits of the PSA Nitrogen generator over traditional sources like cylinders or liquid nitrogen:

- Compact & Movable – Saves space vs large liquid tanks

- Fully Automatic – Auto-stop & idle features optimize energy use.

- In-House Production – No reliance on vendors or logistics.

- Lower Carbon Emissions – Eliminates transport-related CO₂.

- Low Cost – At least 5× cheaper than other nitrogen sources.

Conclusion

Tire pyrolysis is the need of the hour for sustainable waste tire recycling. By the decomposition of used tires and recycling them into useful products.

- Nitrogen gas is indispensable due to its inert nature, safety benefits, cost-efficiency, and abundance.

- While Argon or Helium are alternatives, they are prohibitively expensive.

- The shift from traditional Nitrogen supply (cylinders, liquid tanks) to on-site PSA Nitrogen Generators has transformed the economics of pyrolysis, making the process more profitable and environmentally friendly.

Consult Us

For tailored solutions and cost-efficient nitrogen in the Tire pyrolysis setup, please schedule a consultation with us.

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: absstem.com

References

- Absstem Technologies. (2024). Understanding Nitrogen Purity in PSA Nitrogen Generators

- Absstem Technologies. (2024). How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders

FAQs

Why is nitrogen gas used in tire pyrolysis?

Nitrogen creates an inert atmosphere that prevents oxidation, fire hazards, and unwanted reactions.

What is the required nitrogen purity for tire pyrolysis?

Between 99.5% to 99.9%, ensuring negligible oxygen content.

How much does nitrogen cost for tire pyrolysis?

- Cylinders: ₹75-100/Nm³

- Liquid Nitrogen: ₹15-30/Nm³

- PSA Nitrogen Generator: ₹2.65/Nm³

What pressure of nitrogen is used in tire pyrolysis?

Typically 1-2 Barg.

Why are PSA nitrogen generators preferred?

They provide low-cost, in-house nitrogen generation with zero logistics, automatic controls, and lower carbon footprint.