PSA Nitrogen Generator for Tyre Manufacturing: Ensure Quality & Efficiency

Absstem provides high-quality PSA nitrogen generators across India, specifically designed for tyre manufacturing. These generators deliver a reliable supply of high-purity nitrogen, enhancing processes like curing, vulcanization, and inflation. With Absstem, tyre manufacturers can improve product quality, boost efficiency, and reduce reliance on external nitrogen suppliers.

Tyre Manufacturing

Leading tyre manufacturers are continuously adopting new technologies to enhance productivity, efficiency, and production rates in an increasingly competitive market. One of the recent advancements is the replacement of steam with nitrogen in the tyre curing process.

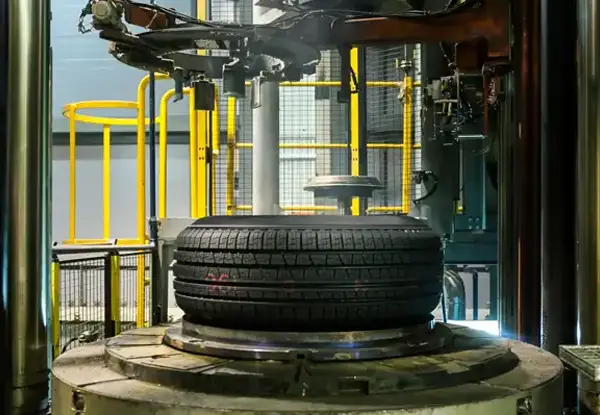

Tyre curing is a critical stage where the tyre attains its final shape and tread pattern. The process is primarily governed by three key parameters: temperature, pressure, and time. During curing, the green Tyre is placed inside a mold and subjected to high pressure and heat over a calculated cycle period. This facilitates the chemical reaction between the base rubber compound and vulcanizing agents, ensuring the Tyre achieves its desired elastomeric properties.

How PSA Nitrogen Generators Improve Tyre Manufacturing Processes

PSA (pressure swing adsorption) nitrogen generators provide a consistent supply of high-purity nitrogen, essential for tyre manufacturing processes like curing, vulcanization, and inflation. They help maintain product quality, enhance operational efficiency, and reduce dependence on external gas suppliers. With these generators, tyre manufacturers can ensure safer and more reliable production.

Key Applications

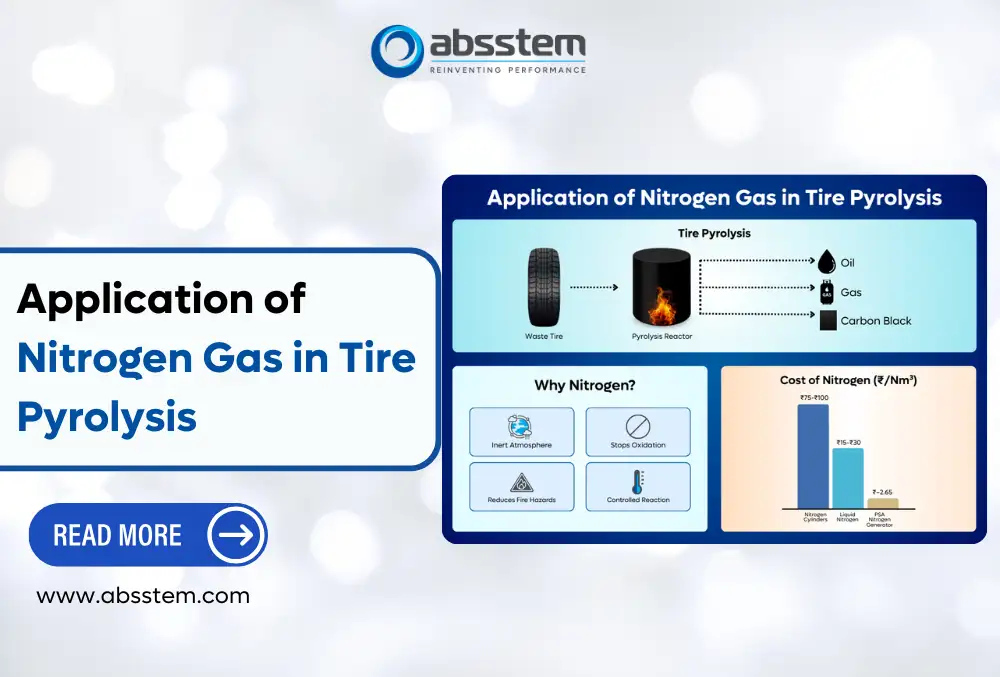

Tyre Curing

Nitrogen is used to inflate curing bladders during tyre vulcanization. It provides uniform pressure, enhances safety, and improves final tyre quality.

Challenges

High cost of steam energy

Need for additional protective antioxidants in some cases

Increased maintenance efforts

Handling difficulties

Risk of quality impairment

Reduced bladder life and longer cycle times

Technical Data

| Purity Level | Pressure | Flow |

|---|---|---|

| 99.99 - 99.995% | 24 - 30 Barg | Contact Us |

Related Products

FAQs

How does nitrogen improve tyre manufacturing processes?

Nitrogen enhances tyre manufacturing by providing an inert atmosphere during curing and vulcanization, reducing oxidation and moisture. This leads to improved product consistency, longer tyre lifespan, and reduced scrap rates.

What are the environmental benefits of using PSA nitrogen generators in tyre manufacturing?

Can PSA nitrogen generators be customized for specific tyre manufacturing needs?

Yes, PSA nitrogen generators can be tailored to meet the required nitrogen purity levels and flow rates for various tyre manufacturing applications, ensuring optimal performance and compliance with industry standards.

What cost savings can tyre manufacturers expect from using PSA nitrogen generators?

By generating nitrogen on-site, tyre manufacturers can significantly reduce costs associated with purchasing and transporting bulk nitrogen. The return on investment is typically realized within two years, depending on usage and system size.

Are PSA nitrogen generators suitable for all tyre manufacturing scales?

PSA nitrogen generators are scalable and can be configured to meet the needs of both small-scale and large-scale tyre manufacturing operations, providing flexibility and efficiency across different production volumes.

Blogs

Absstem Gallery

Trusted By Thousands

Request for Quote

For further information and tailored solutions, please contact us.