The precision demands of modern laser cutting operations require careful control of assist gases. This guide explores nitrogen’s crucial role in the process, from purity requirements to delivery systems.

What is Laser Cutting?

Laser cutting is a precision material processing technique that uses focused laser beams to cut metals and plastics. The process achieves a high-quality finish and has revolutionised metal fabrication through its high-speed cutting capabilities.

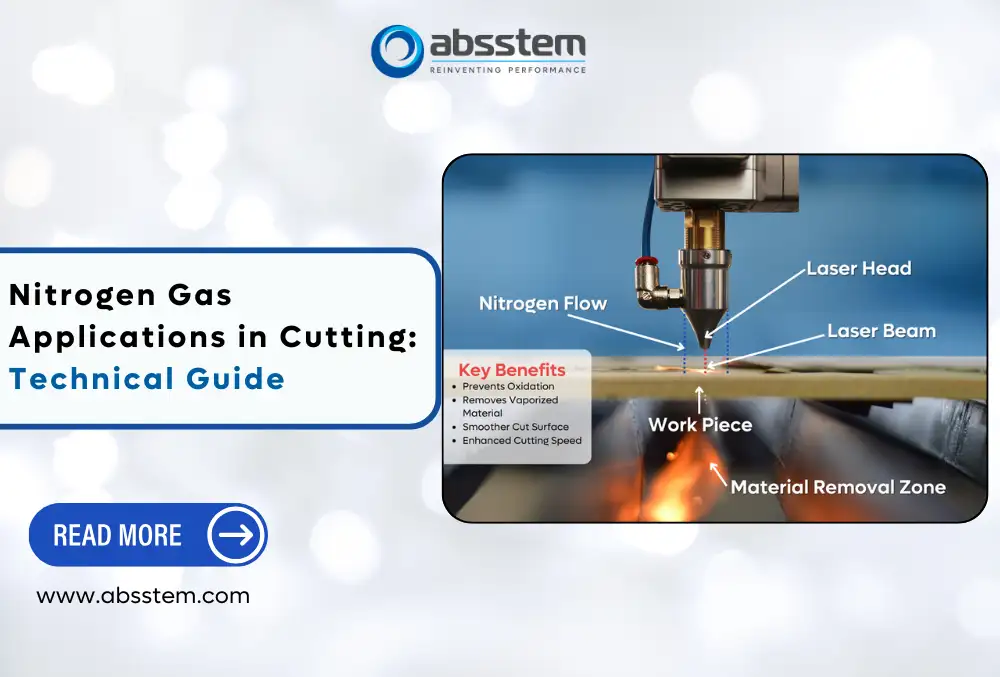

How is Nitrogen utilised in Laser Cutting?

During laser cutting, oxygen must be displaced from the metal surface to prevent oxidation. A non-reactive or inert gas is ideal for this purpose. Since nitrogen is the most abundant inert gas in the atmosphere, it becomes the most economical choice. Nitrogen is used as an assist gas at high pressure and flow to blow away the molten material from the surface during cutting.

Uses of Nitrogen in Laser Cutting

- Prevents oxidation – Nitrogen displaces oxygen from the metal surface.

- Enhances cut quality – Pressurized nitrogen helps remove vaporised material, preventing the solidification of melted material on the cut surface.

- Produces smoother, shinier cuts – Nitrogen improves the overall finish with high precision.

- Increases cutting speed – It aids in heat dissipation and cools the surface faster.

Can other gases be used instead of nitrogen, for Laser Cutting?

Yes, theoretically, other inert gases like argon and helium can be used. However, the cost of production for these gases is significantly higher than that of nitrogen:

Cost of production of Nitrogen ~ 100 times < Cost of production of Argon

Cost of production of Nitrogen ~ 1000 times < Cost of production of Helium

This cost advantage stems from nitrogen’s natural abundance (78%) in Earth’s atmosphere. To understand more about the cost of production of nitrogen via PSA nitrogen generators, please read this blog (1).

What is the Required Purity of Nitrogen for Laser Cutting?

The purity of nitrogen for laser cutting typically ranges between 99.99% and 99.999%. This purity level determines the oxygen content in nitrogen:

- Below 100 PPM oxygen content is generally sufficient for laser cutting.

- Higher purity levels are needed based on the material and required finish quality.

For more insights on nitrogen purity, read our blog titled, Understanding Nitrogen Purity in PSA Nitrogen Generators (1).

How Much Nitrogen is Required for Laser Cutting?

The nitrogen requirement depends on machine specifications and the material thickness to be cut. For example:

- A 2 kW laser machine typically requires 30 Nm³/hr of nitrogen. This requirement varies according to the material thickness, so please consult the OEM of the laser machine to get the exact requirement of Nitrogen.

To calculate the exact nitrogen requirement based on your usage (cylinders or liquid nitrogen tanks), check out our blog titled Calculation of Volume of Gas stored in a High-Pressure Cylinder (2) or contact us directly.

What is the Required Nitrogen Pressure for Laser Cutting in Electronics Manufacturing?

The required pressure varies based on material thickness but typically ranges between 12 to 20 Kg/cm²g. Consult your laser machine OEM for exact pressure requirements.

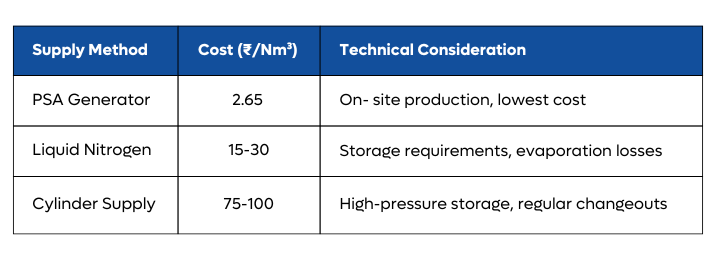

Traditionally, liquid nitrogen tanks or nitrogen cylinders were used as a source of nitrogen gas for purging in laser cutting, but with advancements in technology, Nitrogen nowadays is produced on-site via PSA nitrogen generators which separate nitrogen from atmospheric air.

The cost of nitrogen reduces drastically when produced via a PSA nitrogen generator. The below table shows the cost of Nitrogen by different sources:

We’ve spoken in depth about the cost of various sources of Nitrogen in our blog titled How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders (3).

Can Low-Purity Nitrogen (<99.99%) Be Used for Laser Cutting?

In most cases, 99.99 to 99.999% nitrogen gas is used in laser cutting machines. This will cost you around ₹4.8-8.48/- per cubic meter when produced via PSA Nitrogen Generator. Using a lower purity Nitrogen gas like 99.5 or 99.6 % will affect the finish quality and also will affect the life of the lens in the laser machine. So, Nitrogen purity below 99.99% is not recommended.

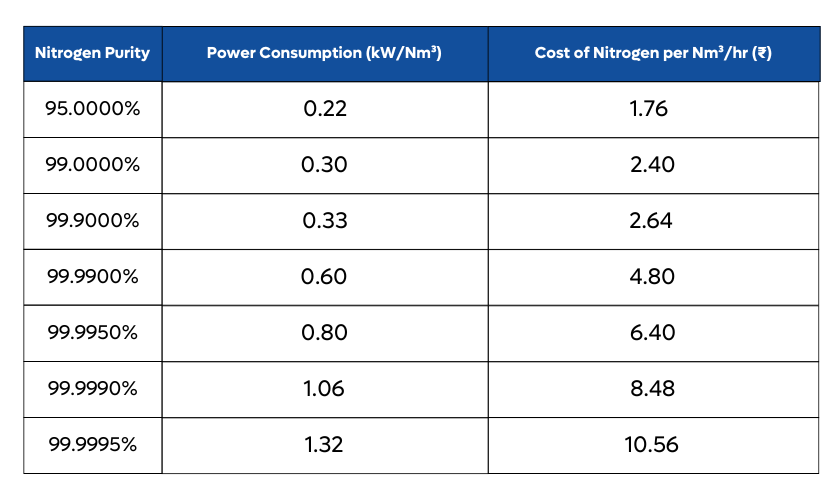

Now the decision to use 99.9 or 99.999% purity will impact the cost of nitrogen. The cost of nitrogen production via PSA technology varies significantly as we move from lower to higher purity. This is mainly because producing higher-purity Nitrogen requires more energy (High amount of compressed air).

For example, generating nitrogen at 95% purity requires significantly less power than producing nitrogen at 99.9990% purity, since removing the final traces of oxygen from the gas mixture is an energy-intensive process.

The table below shows how electricity consumption affects the cost of production of nitrogen at different purity levels, assuming the cost of electricity as ₹8/- per unit – as per our blog (1):

As the table shows, the power consumption—and consequently, the cost—increases as nitrogen purity rises. For instance, producing nitrogen at 99.995% purity costs ₹6.4 per Nm³, whereas producing 99.9995% purity nitrogen costs ₹10.56 per Nm³. This significant difference highlights the need to carefully match the nitrogen purity level to the application requirements to optimize costs. So we recommend choosing the purity of nitrogen wisely between 99.99 and 99.999 %

Why Are PSA Nitrogen Generators the Preferred Choice for Laser Cutting?

Compared to traditional nitrogen sources like cylinders and liquid tanks, PSA nitrogen generators offer significant advantages for an application like being the assist gas in laser cutting. We’ve listed the benefits below::

- Compact Size – A 30 Nm³/hr PSA generator is space-efficient.

- Fully Automatic Operation – Features like auto-stop and IDLE mode enhance efficiency where clients can completely focus on the manufacturing process.

- On-Site Generation – Eliminates dependency on third-party suppliers and logistics for cylinder refilling or liquid tank refillings.

- Lower Carbon Emissions – No transportation and logistics involved.

- Cost Savings – At least 2 times cheaper than other sources.

Conclusion

With the rapid expansion of India’s manufacturing sector, laser-cutting machines have become crucial for improving production speed and quality. Nitrogen’s inert nature, cost-effectiveness, and availability make it the preferred assist gas over alternatives like argon and helium.

While traditional nitrogen sources like liquid nitrogen and cylinders are still used, on-site PSA nitrogen generators have emerged as a cost-effective and sustainable alternative. Understanding the specific requirements of nitrogen for laser cutting allows industries to optimize operations and reduce expenses. For tailored solutions and cost-efficient nitrogen for laser-cutting setups, please schedule a consultation with us.

Contact Us

For tailored solutions and expert advice on Nitrogen usage in laser cutting, contact us:

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: absstem.com

References

- Absstem Technologies. (2024). Understanding Nitrogen Purity in PSA Nitrogen Generators

- Absstem Technologies. (2024). Calculation of Volume of Gas stored in a High-Pressure Cylinder

- Absstem Technologies. (2024). How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders