When you buy packaged food, the freshness, flavor, and safety don’t just depend on the ingredients, it’s also about the invisible atmosphere surrounding them. One critical factor is the gas used in food packaging and processing, particularly nitrogen. To ensure safety and compliance, food-grade nitrogen must meet rigorous standards. A key benchmark is Nitrogen for Food and Beverage Applications (Doc 941/14) (1) published by the European Industrial Gases Association (EIGA).

This guideline defines purity, handling, and storage requirements to guarantee nitrogen’s safe usage in direct contact with food. Let’s explore why this matters and how it impacts the food you eat every day.

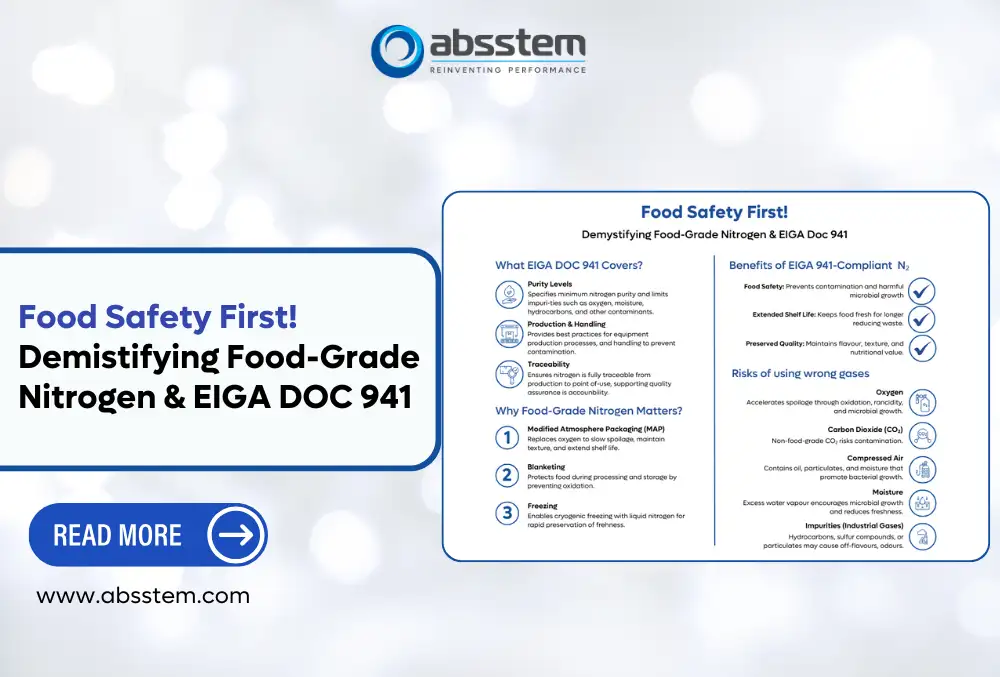

What EIGA Doc 941 Covers

The EIGA 941 document outlines strict standards for food-grade nitrogen, including:

- Purity Levels: Specifies minimum nitrogen purity and limits impurities such as oxygen, moisture, hydrocarbons, and other contaminants.

- Production & Handling: Provides best practices for equipment, production processes, and handling to prevent contamination.

- Traceability: Ensures nitrogen is fully traceable from production to point-of-use, supporting quality assurance and accountability.

By following these standards, food manufacturers can ensure nitrogen is consistently safe for food applications.

Why Food-Grade Nitrogen Matters

Food-grade nitrogen, regulated by standards like EIGA 941, is widely used in:

- Modified Atmosphere Packaging (MAP): Replaces oxygen to slow spoilage, maintain texture, and extend shelf life.

- Blanketing: Protects food during processing and storage by preventing oxidation.

These applications preserve food quality while enhancing safety and reducing food waste.

The Risks of Using the Wrong Gases

Using gases that are not food-grade, or mishandling gases, can introduce significant hazards:

- Oxygen: Accelerates spoilage through oxidation, rancidity, and microbial growth.

- Carbon Dioxide (CO₂): Useful in MAP but can cause off-flavours or discolouration if concentrations are mismanaged. Non-food-grade CO₂ risks contamination.

- Compressed Air: Contains oil, particulates, and moisture that promote bacterial growth.

- Moisture: Excess water vapour encourages microbial growth and reduces freshness.

- Impurities (industrial gases): Hydrocarbons, sulfur compounds, or particulates may cause off-flavours, odours, or even health risks.

This highlights why certified food-grade nitrogen and strict handling protocols are non-negotiable in the food industry.

Benefits of EIGA 941-Compliant Food-Grade Nitrogen

- Food Safety: Prevents contamination and harmful microbial growth.

- Extended Shelf Life: Keeps food fresh for longer, reducing waste.

- Preserved Quality: Maintains flavour, texture, and nutritional value.

The invisible nitrogen shield ensures that what reaches your plate is not just delicious, but also safe.

Conclusion

Food safety is about more than ingredients; it’s about the gases that preserve them. By following EIGA Doc 941 standards, food producers ensure nitrogen used in packaging and processing is pure, traceable, and handled correctly. This invisible yet essential safeguard protects both consumers and manufacturers by maintaining freshness, flavour, and safety.

Consult Us

At Absstem, we specialise in advanced PSA Nitrogen Generators that deliver food-grade nitrogen compliant with global standards like EIGA 941. Whether you’re in food packaging, processing, or freezing applications, our solutions ensure reliability, safety, and cost efficiency. Contact our experts:

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: absstem.com

References

European Industrial Gases Association (EIGA). Nitrogen for Food and Beverage Applications (Doc 941/14).