Pressure Swing Adsorption (PSA) technology is extensively used for generating oxygen and nitrogen gases from atmospheric air. Its efficiency and reliability make it a cornerstone in industries ranging from healthcare to manufacturing. However, the performance of PSA systems is highly sensitive to parameters such as pressure, temperature, and altitude. Understanding these factors is crucial for selecting the right PSA generator for your requirements.

This article delves into how temperature, pressure, and altitude influence PSA systems and provides a guide for optimal selection.

Why This Information Matters

Knowledge of the impact of these factors enables users to:

- Ensure consistent system performance.

- Optimize energy consumption and operational costs.

- Avoid equipment inefficiencies or damage.

Key Factors Influencing PSA Performance

-

Temperature of Input Gas

The performance of PSA systems is highly dependent on the temperature of the input gas. Key considerations include:

- Impact on Molecular Sieves: The adsorption and desorption efficiency of molecular sieves diminishes as the temperature rises. Optimal performance is achieved at an input gas temperature of 20-25°C.

- Ambient Temperature Influence: The temperature of compressed air, fed into the PSA system, increases with increase in ambient temperature. At higher temperatures, molecular sieves lose productivity, leading to lower gas output.

- Potential Damage: Prolonged exposure to temperatures above 80°C can irreversibly damage molecular sieves.

Correction Measures :

- Use pre-cooling systems for regions with high ambient temperatures.

- Always check the correction factors provided by manufacturers for performance deviations outside the ideal range.

-

Pressure

Input gas pressure inside the PSA towers is another critical parameter affecting system performance. The ideal operating pressure varies depending on the type of gas being generated:

- PSA Oxygen Generators:

- Optimal pressure range: 2-3 barg.

- Higher pressures lead to increased air-to-oxygen ratios, requiring more energy per unit of oxygen produced.

- For medical applications, where a minimum pressure of 4 barg is required, additional energy consumption is inevitable.

- PSA Nitrogen Generators:

- Optimal pressure range: 6.5-8 barg.

- Pressures above 8 barg increase energy consumption without proportional productivity gains (You can read more about this in our blog Nitrogen Pressure required for different industrial)(1).

- Pressures below 6 barg significantly reduce the productivity of carbon molecular sieves.

Operational Considerations:

- Excessively high pressures (≥12-13 barg) can cause molecular sieve attrition, resulting in reduced productivity and premature equipment wear.

- Consult manufacturers for correction factors to account for pressure variations.

- PSA Oxygen Generators:

-

Altitude

Altitude plays a significant role in PSA system performance due to its effect on atmospheric pressure:

- Lower Atmospheric Pressure: At high altitudes, the reduced atmospheric pressure decreases the density of the air. As a result, compressors must work harder to achieve the required input pressure for PSA, increasing energy consumption.

- Impact on Specific Power The specific energy required to produce one Nm³ of oxygen or nitrogen rises with altitude.

Recommended Actions:

- Factor in the altitude correction

coefficients provided by the manufacturer when sizing a PSA system. - Ensure compressors are designed to

handle increased workloads at high altitudes.

Practical Considerations for PSA System Sizing

To ensure optimal performance and energy efficiency, gather the following data before selecting a PSA generator:

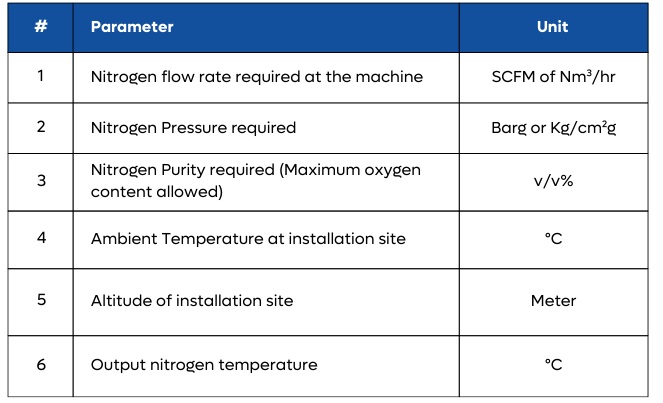

For PSA Nitrogen Generators

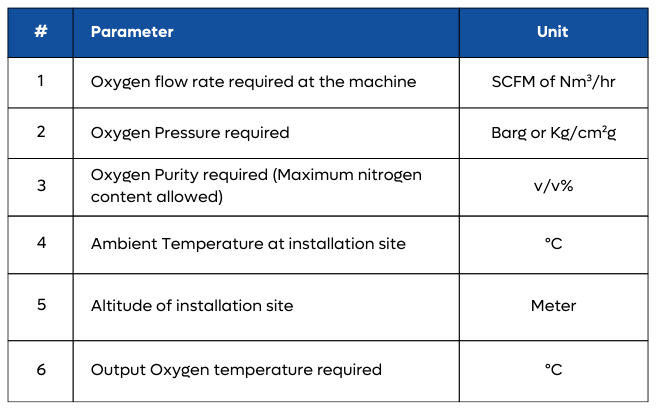

For PSA Oxygen Generators

Output Temperature Considerations

The output temperature of nitrogen or oxygen gas from a PSA plant typically ranges between 20°C and 40°C, depending on the input air temperature. Excessively high input temperatures may require additional cooling mechanisms to stabilize the output.

Conclusion

The performance of PSA oxygen and nitrogen generators is intricately tied to pressure, temperature, and altitude. Understanding these parameters and their interdependencies ensures optimal system selection, reduces operational costs, and prevents equipment inefficiencies.

Before purchasing a PSA system, consult with experienced manufacturers who can tailor the system to your specific environmental conditions.

Contact Us

For expert advice on PSA system selection and optimization:

- Email: [email protected]

- Phone: 1800 3010 3394

Our experienced professionals are here to assist with tailored solutions for your industrial gas needs.

References

- Absstem Technologies. (2024). Nitrogen Pressure required for different industrial applications.