In this blog, we will explore the world of PSA (Pressure Swing Adsorption) technology for the generation of nitrogen and oxygen and analyze its scalability for high-flow applications. Traditionally, cryogenic distillation has dominated large-scale nitrogen and oxygen production. Advancements in PSA Technology, however, have made it a viable alternative.

What is PSA Technology?

PSA Stands for Pressure swing adsorption. Let’s start with understanding adsorption. Adsorption is a surface phenomenon where a certain component gets attached to the outer surface of another component and can be reversibly separated. This property of being a surface phenomenon is what makes it different from absorption.

When this process of attachment and detachment happens due to the difference in the pressure of a gas on molecular sieves, it is called pressure swing adsorption.

PSA technology exploits this principle by using molecular sieves to separate gases based on pressure variations.

What is Cryogenic Distillation?

Cryogenic distillation, as the name suggests occurs at very low temperatures, and is the process of separating components of a mixture by the difference of their respective boiling points. When we talk about the separation of nitrogen and oxygen from atmospheric air, cryogenic distillation is the oldest process and is still used where a large flow of nitrogen or oxygen is required.

Atmospheric air is cleaned and cooled at a very low temperature of -196°C for liquefaction and then fed into a distillation column where components such as nitrogen, oxygen, and argon, are separated based on the difference in their boiling points.

Comparison between PSA and Cryogenic Distillation

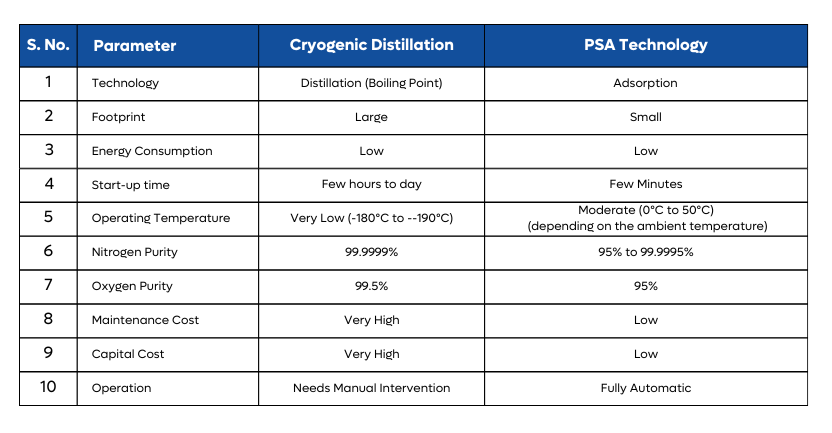

To get clarity about the basic difference between the two technologies for air separation, we have listed the details in the table below:

Large-Scale Applications of PSA vs. Cryogenic Distillation

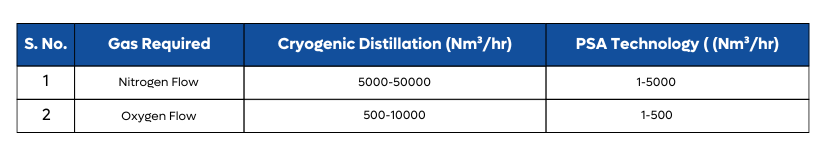

As described in the table above, PSA and Cryogenic distillation have their pros and cons and these advantages decide the application of specific technology in the respective industries. Traditionally, PSA technology has been limited to nitrogen flows below 5000 Nm3/hr, while cryogenic distillation has been used for larger requirements.

For example, traditionally Nitrogen requirements in the range of 10000-30000 Nm3/hr required in steel plants are met by using cryogenic distillation plants whereas nitrogen requirements from 0 – 50003/hr are met via PSA technology.

The table given below shows the traditional use case of PSA and cryogenic technology for air separation based on the quantity of nitrogen or oxygen required by the industry:

The Growing Scalability of PSA Technology

The above example leads to a very important question; Is PSA technology limited to certain flow rates & purity of Nitrogen or oxygen production?

Well, the answer is No. With advancements in the synthesis of molecular sieves and the control over the pore distribution, the productivity and separation efficiency of PSA Technology have improved multi-fold and energy wastage has been reduced significantly.

As PSA Plants are easy to manufacture and operate (due to their simple mechanism), multiple PSA plants connected in parallel are used to cater to large industrial demands which helps save capital expenses and also provides the flexibility to start and stop the generation system as per the actual process requirement. Modern PSA plants now achieve and consistently deliver nitrogen purities of 99.9995% and oxygen purities of 99%.

When is Cryogenic Distillation more Viable than PSA?

There are certain industry requirements where cryogenic technology is a better option than a PSA system, for example, in steel plants, where both oxygen and nitrogen are continuously used in large quantities, a single cryogenic distillation plant can produce both oxygen and nitrogen simultaneously. As both nitrogen and oxygen are consumed by the same industry, the production cost of both oxygen and nitrogen decreases as less energy is consumed for their separation. However, the same does not apply when either Nitrogen or oxygen is required by the industry and that’s where PSA Plants serve as the most effective solution.

Business Models: Renting (OPEX) vs. Equipment Sales (CAPEX)

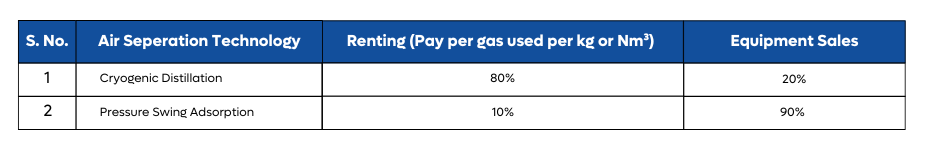

Traditionally, industry requirements are being catered to under CAPEX and OPEX models. The selection of the same is decided based on investment budgets, utility patterns and cost of usage. Accordingly, both technologies hold their merit in OPEX and CAPEX business models

Due to their significantly higher set-up cost, cryogenic plants generally operate on long-term supply contracts, where a customer pays a fixed monthly charge per unit of gas used in their applications. PSA plants, on the other hand, are typically sold as equipment, allowing businesses to generate gas on-site. The table below summarizes the prevalent business models:

With advancements in energy optimization as discussed in our blog titled Possibilities of Advancement in Nitrogen Production via Adsorption (1), more PSA manufacturers are shifting towards a rental model (Pay per gas usage), offering flexible lease terms and taking complete ownership of plant performance throughout the contract period.

Conclusion

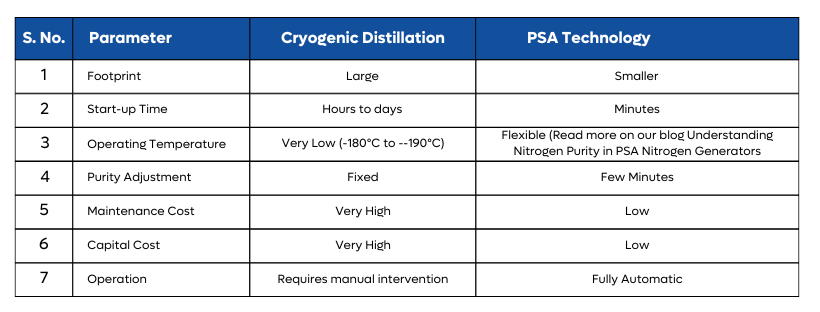

To summarize, both PSA and cryogenic distillation technology have their distinct advantages. While cryogenic distillation is the oldest technology, PSA technology has gained traction due to its lower costs, flexibility, and ease of operation.

Future developments in PSA technology will continue optimizing energy utilization and enhancing gas separation capabilities irrespective of the scale/volume of gas required by any industry

The below table shows the advantage of PSA technology over cryogenic distillation technology for air separation:

Contact Us

For tailored solutions and expert advice on Nitrogen usage in laser cutting, contact us:

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: www.absstem.com

References

- Absstem Technologies. (2024). Possibilities of Advancement in Nitrogen Production via Adsorption

- Absstem Technologies. (2024) Understanding Nitrogen Purity in PSA Nitrogen Generators