Brazing is one of the most reliable methods of joining metals, widely used in industries such as HVAC, automotive, and metal fabrication. At the heart of this process lies oxygen gas, which, when combined with a fuel gas like acetylene, creates the high-temperature flame required for efficient brazing.

In this article, we explore how oxygen gas is used in brazing, its required purity and pressure, the cost comparison between different oxygen sources, and why PSA oxygen generators are becoming the preferred choice for modern industries.

What is brazing?

Brazing is a process where two or more base metals are fused using a filler metal with a melting point lower than that of the base materials. The filler metal (commonly bronze or brass) is drawn into the joint through capillary action.

The most common technique, oxy-fuel brazing, uses a mixture of oxygen and acetylene to produce a concentrated, controllable flame that efficiently heats the metals being joined.

Why Oxygen Is Used in Brazing

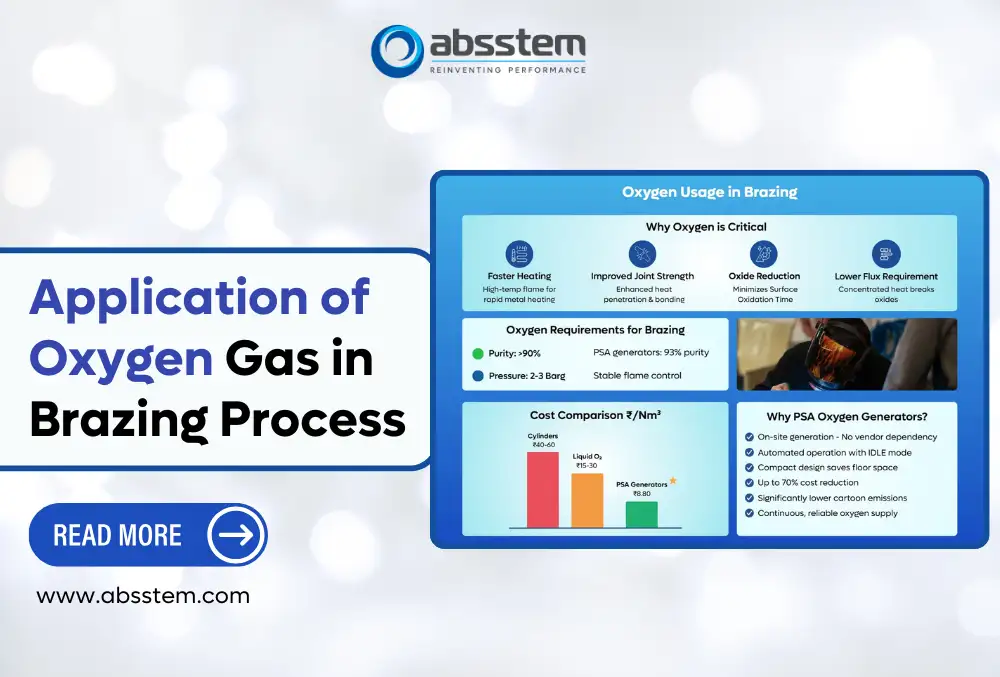

Oxygen is critical in brazing because it enables complete combustion of the fuel gas, resulting in a hotter, more concentrated flame. Key advantages include:

- Faster Heating: Oxygen produces a high-temperature flame (~3100°C with acetylene), ensuring rapid heating and improved filler penetration, which facilitates faster melting of the base material.

- Oxide Reduction: Fast, concentrated heating reduces oxidation time by allowing the base metal to reach brazing temperature almost instantly, ensuring clean joints and superior bond strength.

- Lower Flux Requirement: Concentrated heat helps break surface oxides on the base material, reducing the amount of flux required.

- Improved Joint Strength: Enhanced heat penetration enables deeper filler bonding and enhanced structural strength.

Can Other Gases Be Used for Brazing?

The right answer is yes. Gases like air and propane can also be used. The differences lie in the application and cost of gas and the efficiency of the process. Oxygen is used instead of air for its higher efficiency and quality of joints.

| Gas Type | Typical Use | Flame Temp (°C) | Efficiency | Comments |

| Air + Propane | Low-temp brazing | ~2000 | Low | Suitable for soft metals |

| O₂ + Propane | Medium-temp | ~2800 | Medium | Moderate efficiency |

| O₂ + Acetylene | High-temp | ~3100 | High | Ideal for precision brazing |

Thus, oxygen-acetylene remains the gold standard for precision and productivity.

What is the purity of Oxygen required for the Brazing Industry?

The purity of oxygen gas for brazing applications is more than 90%. PSA oxygen generators producing 93% purity meet industry requirements.

How much Oxygen is required for the Brazing Industry?

The volume of oxygen required for this process is not constant and varies with the flame requirement and the material to be brazed. So, consult the OEM of the torch before deciding the quantity of oxygen required.

What is the Oxygen pressure required for the Brazing Industry?

Oxygen at a pressure of 2-3 Barg is required in the Brazing Industry.

What are the different sources of oxygen in the Brazing Industry?

Traditionally, liquid oxygen tanks or oxygen cylinders were used as a source of oxygen gas for Brazing industry applications, but with advancements in technology, Oxygen is nowadays produced on-site via PSA oxygen generators, which separate oxygen from atmospheric air.

The cost of oxygen reduces drastically when produced via a PSA oxygen generator. The table below shows the cost of Oxygen from different sources:

| Source | Cost (₹/Nm³) | Pressure | Remarks |

| Oxygen Cylinders | 40-60 | Up to 200 Barg | Requires regular refilling and logistics |

| Liquid Oxygen | 15-30 | Up to 20 Barg | Higher storage & transport costs |

| PSA Oxygen Generator | 8.80 | Up to 250 Barg | On-site generation; lowest cost |

To read more about the cost of different sources of oxygen, please read our blog titled How to Calculate the ROI (Return on Investment) of a PSA Oxygen Generator Compared to Liquid Oxygen or Oxygen Cylinders (1).

Can oxygen purity of 93% be used for the Brazing Application?

Yes. Oxygen purity of more than 90% is sufficient for brazing applications, so PSA oxygen generators are widely used in brazing to reduce the cost of oxygen compared to traditional sources.

Why PSA Oxygen Generators Are Ideal for Brazing Applications

Compared to the traditional sources of oxygen gas like cylinders or liquid tanks, PSA oxygen generators are far more beneficial for an application like Brazing. Below are the benefits of the PSA Oxygen generator over traditional sources like cylinders or liquid oxygen:

PSA oxygen generators extract oxygen directly from ambient air using molecular sieves. They provide a continuous, reliable, and cost-effective oxygen supply.

Advantages:

- Compact Design: Saves valuable floor space compared to liquid storage tanks.

- Automated Operation: Modern PSA systems feature auto-stop and IDLE modes, optimising power use based on demand.

- In-House Oxygen Production: Eliminates vendor dependency and refilling downtime.

- Reduced Carbon Emissions: No transport or logistics, therefore significantly lower carbon footprint.

- Low Cost of Ownership: Oxygen from PSA is at least 2 times cheaper than a cylinder or LOX supply.

Industry Applications

- Automotive and Radiator Manufacturing

- HVAC (Air Conditioning and Refrigeration Systems)

- Plumbing and Copper Piping Industries

- Tool and Die Manufacturing

Conclusion

Oxygen is indispensable for brazing, ensuring faster heating, cleaner joints, and superior bond strength. With the advent of PSA oxygen generation systems, industries can now produce high-purity oxygen on-site, drastically reducing operational costs and carbon emissions.

Brazing is an important application for a lot of industries, including automobiles, AC manufacturing, etc., and a reduction in the cost of oxygen is of utmost importance for such industries, and PSA oxygen generators can be a boon.

While traditional oxygen sources like liquid oxygen and cylinders are still used, on-site PSA oxygen generators have emerged as a cost-effective and sustainable alternative. Understanding the specific requirements of oxygen for Brazing applications allows industries to optimise operations and reduce expenses.

Consult Us

For tailored solutions and cost-efficient oxygen for Brazing application setups, please schedule a consultation with us.

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: absstem.com

References

Absstem Technologies. (2024). How to calculate the ROI (Return on Investment) of a PSA Oxygen generator compared to Liquid Oxygen or Oxygen Cylinders