When we talk about the application of a product like nitrogen gas in the field of purging, several questions come to our minds. In this blog, we will try to answer the most common questions regarding the usage of Nitrogen gas in purging. Without further ado, let’s dive into them.

What is Purging?

Purging is the process of displacing unwanted particles or substances, from a container, pressure vessel or pipeline, with inert gas. The most commonly used gas to displace or remove Oxygen is Nitrogen.

Why is Nitrogen used for Purging?

Nitrogen is an inert gas, i.e. Nitrogen does not react with other elements. Since purging is required to remove hazardous or reactive substances from an existing environment inside a pipe or container, a non-reactive gas like Nitrogen is an apt solution.

What are the benefits of Purging?

Nitrogen purging has various benefits and differs based on applications.

- In Food Packaging, it reduces Oxidation thereby increasing shelf-life.

- In Metal Manufacturing, it reduces oxidation as oxygen is reactive in nature.

- In Pharmaceuticals, it removes unwanted gases from containers before starting a new batch.

- In Oil and Gas, it ensures safety by displacing harmful & reactive gases.

Apart from Nitrogen, can we use other gases for Purging?

The right answer is yes. Theoretically, inert gases like argon and helium can also be used. The differences lie in the cost of production of these gases.

Cost of production of Nitrogen ~ 100 times < Cost of production of Argon

Cost of production of Nitrogen ~ 1000 times < Cost of production of Helium

Therefore, Nitrogen becomes the best solution. The reason for the low cost of production of nitrogen is the availability of abundant nitrogen (78%) in the atmosphere.

To understand more about the cost of production of nitrogen via PSA nitrogen generators, please read this blog (1).

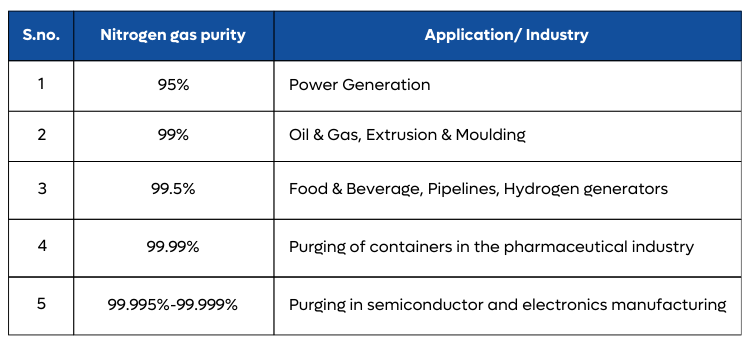

What is the purity of Nitrogen required for Purging?

The purity of nitrogen gas for purging varies with different applications. We’ve tabulated this below:

How much Nitrogen is required for Purging?

This always depends on the application, but as a thumb rule, we use

What is the Nitrogen pressure required for Purging?

A positive pressure of nitrogen in the range of 0.5 to 1.5 Kg/cm2g is required for purging but in certain cases where the substance to be displaced is filled at higher pressure, the pressure of nitrogen needs to be higher than that of the filled substance.

What are the different sources of Nitrogen for purging?

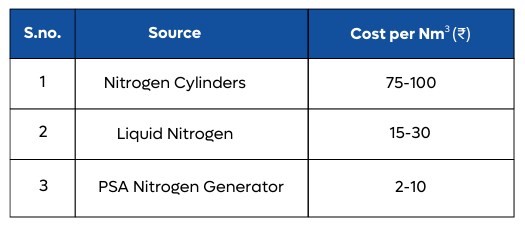

Traditionally, liquid nitrogen tanks or nitrogen cylinders were used as a source of nitrogen gas for purging applications, but with advancements in technology, Nitrogen nowadays is produced on-site via PSA nitrogen generators which separate nitrogen from atmospheric air.

The cost of nitrogen reduces drastically when produced via a PSA nitrogen generator system. The below table shows the cost of Nitrogen by different sources:

We’ve spoken in depth about the cost of various sources of Nitrogen in our blog titled How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders (2).

Can High-Purity Nitrogen (99.99 or 99.999%) be used for Purging?

High-purity nitrogen (99.99% or 99.999%) can theoretically be used for purging, but in our experience, a purity level between 99.5% and 99.9% is more practical and cost-effective. While any purity level can be used, higher purity comes at a significantly higher cost, as explained below.

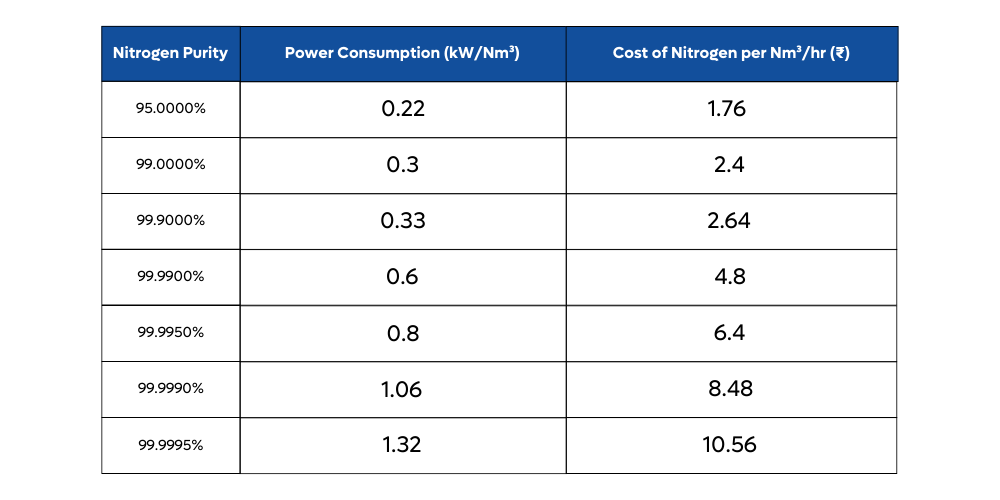

The cost of nitrogen varies with the purity of nitrogen required so it varies from ₹1.76/- (95.000% Purity) to ₹10.56/- (99.9995% Purity) per cubic meter.

In most cases, 99.5000% nitrogen is used for purging. This will cost you around ₹3/- per cubic meter when produced via PSA Nitrogen Generator.

The cost of nitrogen production via PSA technology varies significantly as we move from lower to higher purity. This is mainly because producing higher-purity Nitrogen requires more energy (High amount of compressed air).

For example, generating nitrogen at 95% purity requires significantly less power than producing nitrogen at 99.9990% purity, since removing the final traces of oxygen from the gas mixture is an energy-intensive process.

The table below shows how electricity consumption affects the cost of production of nitrogen at different purity levels, assuming the cost of electricity as ₹8/- per unit – as per our blog (1):

As the table shows, the power consumption—and consequently, the cost—increases as nitrogen purity rises.

For instance, producing nitrogen at 95% purity costs ₹1.76 per Nm³, whereas producing 99.9995% purity nitrogen costs ₹10.56 per Nm³. This significant difference highlights the need to carefully match the nitrogen purity level to the application requirements to optimize costs.

Will a standard PSA nitrogen generator work for purging applications?

Well, not really. As purging is not required continuously and the volume of nitrogen required also varies with time, a standard PSA nitrogen generator will result in energy wastage.

Certain applications like the purging of pipelines after a batch require huge volumes of nitrogen but for a short duration. In such cases, PSA nitrogen generators with large storage tanks are required to cater for the sudden demand.

In case your application also requires large nitrogen volumes for a short duration, please get in touch with us to save on both, operational as well as capital costs.

Conclusion

Nitrogen purging is a critical process across multiple industries. Its inert nature, cost-effectiveness, and availability make nitrogen the preferred choice over other inert gases like argon and helium.

While traditional nitrogen sources like liquid nitrogen and cylinders are still used, on-site PSA nitrogen generators have emerged as a cost-effective and sustainable alternative. Understanding the specific requirements of nitrogen for purging allows industries to optimize operations and reduce expenses. For tailored solutions and cost-efficient nitrogen purging setups, please schedule a consultation with us.

Consult Us

For tailored solutions and expert advice on Nitrogen usage in Purging, contact us:

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: absstem.com

References

- Absstem Technologies. (2024). Understanding Nitrogen Purity in PSA Nitrogen Generators

- Absstem Technologies. (2024). How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders