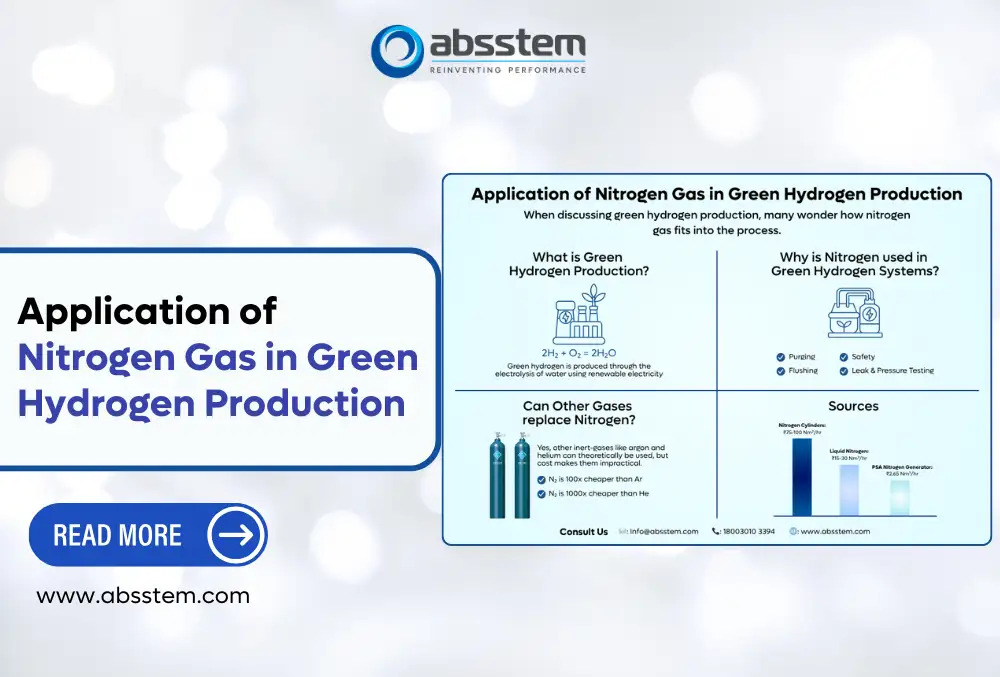

When discussing green hydrogen production, many wonder how nitrogen gas fits into the process. In this blog, we’ll answer the most common questions about nitrogen’s role in green hydrogen projects. Without further ado, let’s dive into them.

What is Green Hydrogen Production?

Green Hydrogen production is the process of hydrogen generation through the electrolysis of water, where H₂O is split into hydrogen (H₂) and oxygen (O₂). The electricity used comes from renewable sources such as solar or wind energy – hence the term green hydrogen.

Why is Nitrogen Used in Green Hydrogen Systems?

While nitrogen is not directly used for hydrogen production, it plays a crucial role during start-up, commissioning, maintenance, and safety operations of the electrolyser and other equipment. It is mostly used in purging and flushing, as it helps in removing oxygen and ensures the safety of the system. Key applications include:

- Purging

- Hydrogen is flammable when its concentration in oxygen lies between 4% and 95%.

- During start-up, pipelines and equipment contain air (20.9% oxygen); if hydrogen passes through them, it may fall within the flammable range.

- To ensure safety, the system is purged with nitrogen, reducing oxygen levels below 1%.

- Nitrogen is also used during maintenance shutdowns for purging.

- Flushing

- In case of emergencies or sudden spikes in oxygen levels, large volumes of nitrogen are flushed through the system to eliminate oxygen.

- Safety

- Nitrogen’s inert nature helps maintain a safe atmosphere in this high-risk process, minimising explosion hazards.

- Green Ammonia Production

- Hydrogen from electrolysis is combined with nitrogen via the Haber-Bosch process to produce green ammonia. (More details in a separate blog that will be published soon)

- Purging

Can Other Gases Replace Nitrogen for Green Hydrogen production or leak testing?

The right answer is yes. Theoretically, inert gases like argon and helium can also be used. The differences lie in the cost of production of these gases.

Cost of production of Nitrogen ~ 100 times < Cost of production of Argon

Cost of production of Nitrogen ~ 1000 times < Cost of production of Helium

Therefore, Nitrogen becomes the best solution. The reason for the low cost of production of nitrogen is the availability of abundant nitrogen (78%) in the atmosphere.

To understand more about the cost of production of nitrogen via PSA nitrogen generators, please read our blog titled Understanding Nitrogen Purity in PSA Nitrogen Generators (1).

What purity of Nitrogen is required for Green Hydrogen production?

The purity of nitrogen gas for Green Hydrogen production varies between 99.5 to 99.9%, where these purities of nitrogen signify the oxygen content present in nitrogen. To get more clarity about the purity of nitrogen gas, please read our blog titled Understanding Nitrogen Purity in PSA Nitrogen Generators (1).

How much Nitrogen is required for Green Hydrogen production?

The volume of nitrogen requirement for this process is not constant and varies over time, and also requires a sudden flush of nitrogen for certain moments. So consult the OEM of the electrolyser before deciding the quantity of nitrogen required. Please read our blog titled How to Select the Right Nitrogen Plant for Varying Nitrogen Requirement: Part II (2), to know more.

What is the Nitrogen pressure required for Green Hydrogen production?

Nitrogen at a pressure of 4 – 30 Barg is required for the Green Hydrogen production process.

What are the different sources of nitrogen for Green Hydrogen Production?

Traditionally, liquid nitrogen tanks or nitrogen cylinders were used as a source of nitrogen gas for Green Hydrogen production applications. With advancements in technology, however, nitrogen is nowadays produced on-site via PSA nitrogen generators, which separate nitrogen from atmospheric air.

The cost of nitrogen reduces drastically when produced via a PSA nitrogen generator. The table below shows the cost of Nitrogen from different sources:

| Sr. No. | Source | Cost of Nitrogen Per Nm3/hr (₹) | Pressure of Nitrogen |

| 1 | Nitrogen Cylinders | 75-100 | Up to 200 Barg |

| 2 | Liquid Nitrogen | 15-30 | Up to 20 Barg |

| 3 | PSA Nitrogen Generator | 2.65 | Up to 250 Barg |

Please note: Nitrogen from the PSA nitrogen generator is produced at a pressure of around 8 Barg, and it is then pressurised via a booster to the required nitrogen pressure. The cost of boosting is still lower compared to the generation cost, so we have ignored the cost in the above table.

To read more about the cost of different sources of nitrogen, please read our blog titled How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders (3).

Can high-purity nitrogen of 99.99 or 99.999% be used for Green Hydrogen production?

In most cases, 99.9 %% nitrogen gas is used for Green Hydrogen production. This will cost you around ₹2.6/- per cubic meter when produced via PSA Nitrogen Generator.

The cost of nitrogen production via PSA technology varies significantly as we move from lower to higher purity. This is mainly because producing higher-purity Nitrogen requires more energy (High amount of compressed air).

For example, generating nitrogen at 95% purity requires significantly less power than producing nitrogen at 99.9990% purity, since removing the final traces of oxygen from the gas mixture is an energy-intensive process.

The table below shows how electricity consumption affects the cost of production of nitrogen at different purity levels, assuming the cost of electricity as ₹8/- per unit – as per our blog (1).

Table 1: Cost of Nitrogen used

| Nitrogen Purity | Power (kW/Nm³) | Cost (₹/Nm³/hr) |

| 95.0000% | 0.22 | 1.76 |

| 99.0000% | 0.30 | 2.40 |

| 99.9000% | 0.33 | 2.64 |

| 99.9900% | 0.60 | 4.80 |

| 99.9950% | 0.80 | 6.40 |

| 99.9990% | 1.06 | 8.48 |

| 99.9995% | 1.32 | 10.56 |

As the table shows, the power consumption, and consequently, the cost, increases as nitrogen purity rises.

For instance, producing nitrogen at 95% purity costs ₹1.76 per Nm³, whereas producing 99.9995% purity nitrogen costs ₹10.56 per Nm³. This significant difference highlights the need to carefully match the nitrogen purity level to the application requirements to optimise costs.

Why PSA Nitrogen Generators are the preferred choice for Green Hydrogen production application?

Compared to the traditional sources of nitrogen gas like cylinders or liquid tanks, PSA nitrogen generators are far more beneficial for an application like Green Hydrogen production. Below are the benefits of the PSA Nitrogen generator over traditional sources like cylinders or liquid nitrogen:

- Compact Size: Compact nitrogen generators are help in saving a lot of space compared to liquid tanks

- Fully Automatic Systems: As advanced PSA nitrogen generators are fully automatic with auto stop and IDLE features, these systems prove to be a boon for Green Hydrogen production applications, as nitrogen usage is not constant and varies with time. PSA nitrogen generators go into IDLE mode during low usage of nitrogen to save energy.

- In-house Nitrogen Production: As Nitrogen is produced on-site in PSA nitrogen generators from compressed air, there is no dependency on 3rd party vendors and logistics for refilling of gas, like in the case of cylinders or liquid tanks.

- Lower Carbon emissions: As nitrogen is produced onsite in PSA nitrogen generators, there is no logistics involved, hence carbon emissions are negligible.

- Lowest Cost of Nitrogen: Nitrogen produced by the PSA nitrogen generator is at least 5 times cheaper than other sources

Conclusion

Green Hydrogen production is a critical process, and safety is of utmost importance in this process due to the explosive nature of hydrogen and nitrogen, ensuring the safety of the system in case of any abnormality or startups. Its inert nature, dryness, cost-effectiveness, and availability make nitrogen the preferred choice over other inert gases like argon and helium.

While traditional nitrogen sources like liquid nitrogen and cylinders are still used, on-site PSA nitrogen generators have emerged as a cost-effective and sustainable alternative. Understanding the specific requirements of nitrogen for Green Hydrogen production allows industries to optimise operations and reduce expenses..

Consult Us

For tailored solutions and cost-efficient nitrogen for Green Hydrogen production setups, please schedule a consultation with us:

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: absstem.com

References

- Absstem Technologies. (2024). Understanding Nitrogen Purity in PSA Nitrogen Generators

- Absstem Technologies. (2025). How to Select the Right Nitrogen Plant for Varying Nitrogen Requirement: Part II

- Absstem Technologies. (2024). How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders