The concept of Grade 5 Nitrogen, or 99.999% purity nitrogen, often sparks debates regarding its production, cost, and applications. With the growing popularity of PSA (Pressure Swing Adsorption) nitrogen generators, it’s essential to separate myths from realities. This article explores common statements about Grade 5 Nitrogen, clarifying misconceptions and presenting factual insights in a structured manner.

-

1. 99.999% nitrogen means 10 PPM oxygen content in nitrogen.

Reality.

Explanation: Grade 5 Nitrogen, or 99.999% purity nitrogen from the PSA Nitrogen Plant, contains only 10 parts per million (PPM) of oxygen. This residual oxygen content is critical in applications where nitrogen’s inert nature is essential, and oxygen acts as a contaminant so nitrogen purity is defined in terms of residual oxygen content. PSA nitrogen plants achieve this level of purity efficiently. Learn more about different nitrogen purities in our blog on Nitrogen Pressure Required for Different Industrial Applications (1). -

2. High-purity nitrogen can only be produced via liquid nitrogen.

Myth.

Explanation: While liquid nitrogen is highly pure, PSA technology can also produce 99.999% nitrogen. The PSA process is more cost-effective and eliminates the need for transportation and storage, making it a preferred choice for industries. Liquid nitrogen is generated through air distillation, requiring ongoing refills. Conversely, PSA systems provide on-site production, reducing dependency on external supplies. -

3. Ammonia or hydrogen is required to produce 99.999% nitrogen via PSA technology.

Myth.

Explanation: The conventional approach to generating high-purity nitrogen using PSA technology involves a process known as the deoxo reaction, where oxygen is removed from the gas stream with the help of a palladium catalyst. This reaction requires hydrogen, which reacts with oxygen to form water, eliminating oxygen content. Given the high cost of hydrogen, cracked ammonia is often used as an alternative. Ammonia (NH3) undergoes cracking to produce nitrogen and hydrogen, which are then utilised in this process. Typically, PSA nitrogen plants produce nitrogen with a purity of 99.5% to 99.9%, and the remaining oxygen is removed using the deoxo method.

In contrast, modern PSA nitrogen generators can directly produce nitrogen with up to 99.9995% purity from compressed air, completely eliminating the need for hydrogen or ammonia. The reliance on ammonia or hydrogen poses challenges for the industry due to added costs and safety concerns. These advancements in PSA technology have addressed these issues, making high-purity nitrogen production more cost-effective and safer. -

4. Liquid nitrogen is cheaper than high-purity nitrogen produced by PSA plants.

Myth.

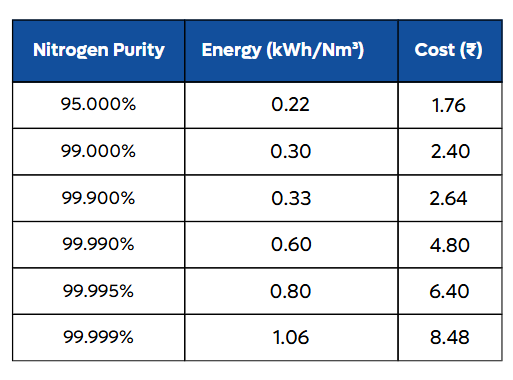

Explanation: Producing nitrogen via PSA technology is significantly cheaper than liquid nitrogen. The cost per cubic meter of nitrogen depends on purity levels, as detailed below:Table A – Cost of Nitrogen gas produced via standard PSA Nitrogen

plant at different purities. ( Considering unit Power Tariff at ₹8/-)

- With a much lower production cost, PSA systems often deliver an ROI within 6–24 months. To calculate ROI for your setup, refer to our article How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinder (2).

-

5. 99.999% nitrogen is better for every application.

Myth.

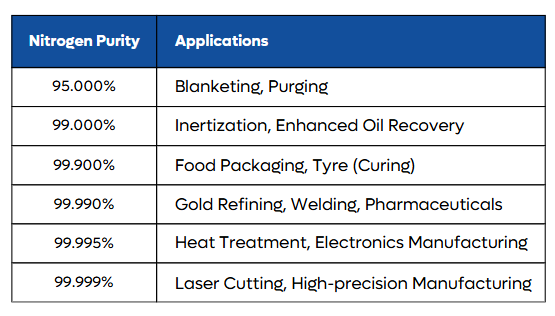

Explanation: Nitrogen with 99.999% purity is superior to lower purity levels due to oxygen’s role as a contaminant in nitrogen gas applications. However, producing nitrogen at such high purity levels via PSA technology significantly increases the cost of production. Table A outlines these costs, demonstrating that only a few industrial applications require nitrogen with 99.999% or higher purity.

For instance, the unit cost of producing 99.999% nitrogen is ₹8.48 per Nm³, approximately 3.5 times the cost of producing 99.9% nitrogen (₹2.64 per Nm³). Using high-purity nitrogen for applications where lower purities suffice leads to unnecessary energy consumption and higher operational expenses. The table below illustrates the specific nitrogen purity levels required across various industries, highlighting the scenarios where lower purity nitrogen is adequate and cost-efficient.

Many industries can operate efficiently with lower purities, as outlined below:

-

6. Consistent 99.999% nitrogen can only be supplied by liquid nitrogen.

Reality.

Explanation:Modern PSA nitrogen plants produce consistent 99.999% nitrogen on-site without external dependencies. The compressed air used ensures a steady supply, outperforming liquid nitrogen in terms of cost and reliability. -

7. Topping up molecular sieves is regularly required in PSA nitrogen plants

Reality.

Explanation: Properly designed PSA plants with well-packed molecular sieve beds rarely require topping up. Poor design or high gas velocity can cause sieve wear, but leading manufacturers like Absstem offer long-lasting solutions with warranties of up to 10 years. For more on molecular sieves, visit our dedicated article titled Understanding Molecular Sieves or Adsorbents: CMS & ZMS (3). -

8. The startup time of a 99.999% PSA nitrogen plant is very high (1–2 hours).

Reality.

Explanation: Modern PSA plants have a startup time of just 5–10 minutes, depending on the manufacturer. This rapid readiness supports continuous industrial operations . -

9. The ROI of a high-purity PSA nitrogen plant is over 5 years.

Reality.

Explanation: As shown in the cost table, PSA nitrogen plants deliver nitrogen at roughly one-third the cost of liquid nitrogen. Depending on the scale and usage, the ROI typically ranges from 6 to 24 months, making these systems highly economical. To calculate ROI for your setup, refer to our article How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinder (2).

Conclusion

Grade 5 Nitrogen, or 99.999% purity, is crucial for many industrial applications, but understanding the nuances of its production and costs is vital. PSA nitrogen plants have revolutionized the industry by offering high-purity nitrogen at a fraction of the cost of liquid nitrogen. By debunking myths and presenting facts, this article aims to empower industries to make informed decisions about their nitrogen requirements.

Contact Us

For tailored solutions and expert advice on PSA systems, reach out to Absstem at:

📧 [email protected]

📞 1800 3010 3394

References

- Absstem Technologies. (2024). Nitrogen Pressure Required for Different Industrial Applications.

- Absstem Technologies. (2024). How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinder.

- Absstem Technologies. (2024). Understanding Molecular Sieves or Adsorbents: CMS & ZMS