While exploring the use of nitrogen gas in 3D printing, several questions naturally arise. In this blog, we’ll address the most common queries about its applications and benefits. Let’s dive in!

What is 3D Printing?

3D printing is the process of manufacturing three-dimensional objects from a digital design (CAD) file by layering thin sheets of material, one above the other.

Why is Nitrogen used for 3D Printing?

During 3D printing, oxygen is required to be displaced from the build chamber to prevent oxidation and ensure a stable environment. A non-reactive or inert gas is the ideal solution and Nitrogen, being the most abundant inert gas (78% of air), Serves as the most economical fit.

What are the uses of Nitrogen in 3D Printing?

- Oxygen Displacement: Removal of oxygen from the build chamber to prevent oxidation.

- Inert Atmosphere Creation: Helps in reducing thermal deformation of the printed object

- Better Product Quality: Helps in achieving better product quality by assuring precisional dimensional accuracy in less time and helping in reducing wastage.

- Enhanced Safety: 3D printing, being a heat-generating process, nitrogen (inert) ensures a safe environment in the build chamber as oxygen is removed by purging

Can we use other gases instead of Nitrogen for 3D Printing?

Yes, other inert gases like argon and helium can also be used, but cost is a major factor.

Cost of production of Nitrogen ~ 1000 times < Cost of production of Helium

Due to its availability and lower cost, nitrogen is the preferred choice for 3D printing.

To understand more about the cost of production of nitrogen via PSA nitrogen generators, please read this blog (1).

What is the required purity of Nitrogen for 3D Printing?

The ideal nitrogen purity for 3D printing is between 99.5% and 99.9%. This ensures a controlled environment with minimal oxygen.

For a detailed breakdown of nitrogen purity levels, read our blog: Understanding Nitrogen Purity in PSA Nitrogen Generators (1).

How much Nitrogen is required for 3D Printing?

On average, 5-7Nm³/hr of nitrogen is required for 3D printers. However, this varies based on OEM specifications, so please check with your 3D printer manufacturer for exact requirements.

What is the required Nitrogen pressure for 3D Printing?

A positive pressure of nitrogen in the range of 0.5 to 1.5 Kg/cm2g is required for 3D Printing.

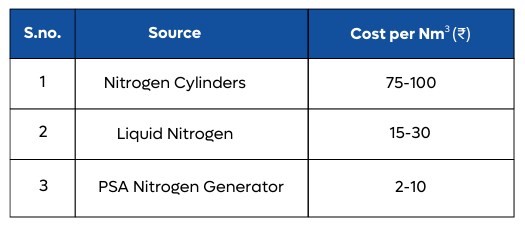

What are the different sources of nitrogen for 3D Printing?

Traditionally, nitrogen for 3D printing came from cylinders or liquid nitrogen tanks, but on-site nitrogen generators have emerged as the most cost-effective solution.

The cost of nitrogen reduces drastically when produced via a PSA nitrogen generator. The below table shows the cost of Nitrogen by different sources:

We’ve spoken in depth about the cost of various sources of Nitrogen in our blog titled How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders (2).

Can high-purity nitrogen of 99.99 or 99.999% be used for 3D printing?

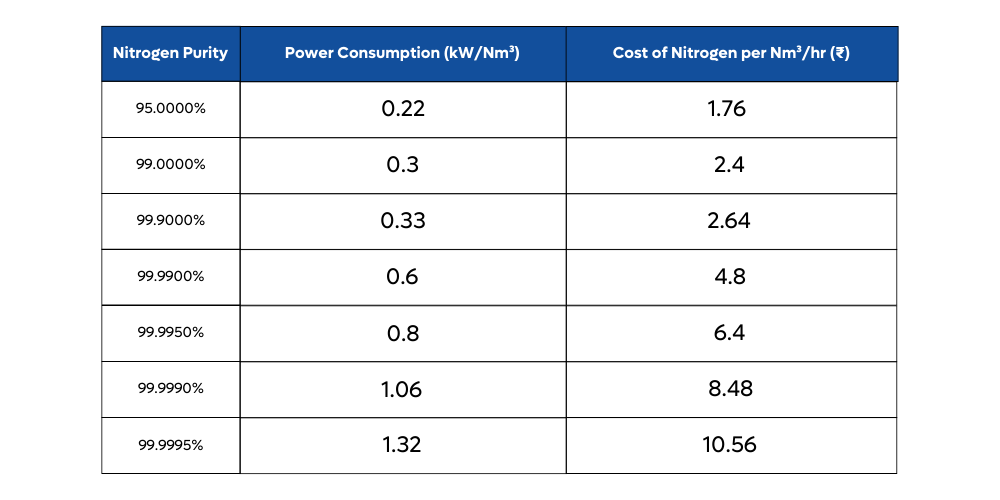

While high-purity nitrogen can be used, it is not necessary for 3D printing, as the generation cost increases significantly with higher purity levels. In most cases, 99.5 to 99.9% nitrogen gas is best suited for 3D Printing and costs around ₹2.6/- per cubic meter when produced via PSA Nitrogen Generator.

The cost of nitrogen production via PSA technology varies significantly as we move from lower to higher purity. This is mainly because producing higher-purity Nitrogen requires more energy (High amount of compressed air).

For example, generating nitrogen at 95% purity requires significantly less power than producing nitrogen at 99.9990% purity, since removing the final traces of oxygen from the gas mixture is an energy-intensive process.

The table below shows how electricity consumption affects the cost of production of nitrogen at different purity levels, assuming the cost of electricity as ₹8/- per unit – as per our blog (1):

As the table shows, the power consumption—and consequently, the cost—increases as nitrogen purity rises.

For example, producing nitrogen at 95% purity costs ₹1.76 per Nm³, whereas producing 99.9995% purity nitrogen costs ₹10.56 per Nm³. This difference highlights the need to match the nitrogen purity level to the requirements to optimize costs.

Why are PSA Nitrogen Generators the preferred choice for 3D Printing?

Compared to traditional sources of nitrogen gas like cylinders or liquid tanks, PSA nitrogen generators are far more beneficial for an application like 3D printing. Below are the benefits of a PSA Nitrogen generator over traditional sources like cylinders or liquid nitrogen:

- Compact Size: A 5 Nm³/hr PSA generator saves space compared to liquid nitrogen tanks.

- Lower Pressure (Safer): Operates at 5-6 Kg/cm²g, which is 30 times lower than cylinder pressure.

- Fully Automatic: Advanced PSA generators have auto-stop and IDLE features, allowing users to focus on 3D printing without gas supply concerns.

- On-Site Nitrogen Production: Eliminates dependence on third-party suppliers and logistics costs.

- Eco-Friendly: No transportation means lower carbon emissions.

- Cost Savings: Nitrogen from PSA generators is at least 5 times cheaper than other sources.

Conclusion

3D Printing is a critical process that requires a stable and inert atmosphere which makes Nitrogen gas the preferred choice due to its availability and affordability.

While traditional nitrogen sources like liquid nitrogen and cylinders are still used, on-site PSA nitrogen generators have emerged as a cost-effective and sustainable alternative.

Contact Us

Please schedule a consultation with us for tailored solutions and cost-efficient nitrogen for 3D Printing setups:

- Email: [email protected]

- Phone: 1800 3010 3394

- Website: www.absstem.com

References

- Absstem Technologies. (2024). Understanding Nitrogen Purity in PSA Nitrogen Generators

- Absstem Technologies. (2024). How to calculate the ROI (Return on Investment) of PSA Nitrogen Generator compared to Liquid Nitrogen or Nitrogen Cylinders